Introduction to Stainless Steel Stamping Parts

Stainless steel stamping parts are widely used in various industries due to their durability, corrosion resistance, and cost-effectiveness. The process involves shaping stainless steel sheets into desired forms using specialized machinery. This guide explores everything you need to know about stainless steel stamping parts, from manufacturing techniques to their applications and advantages.

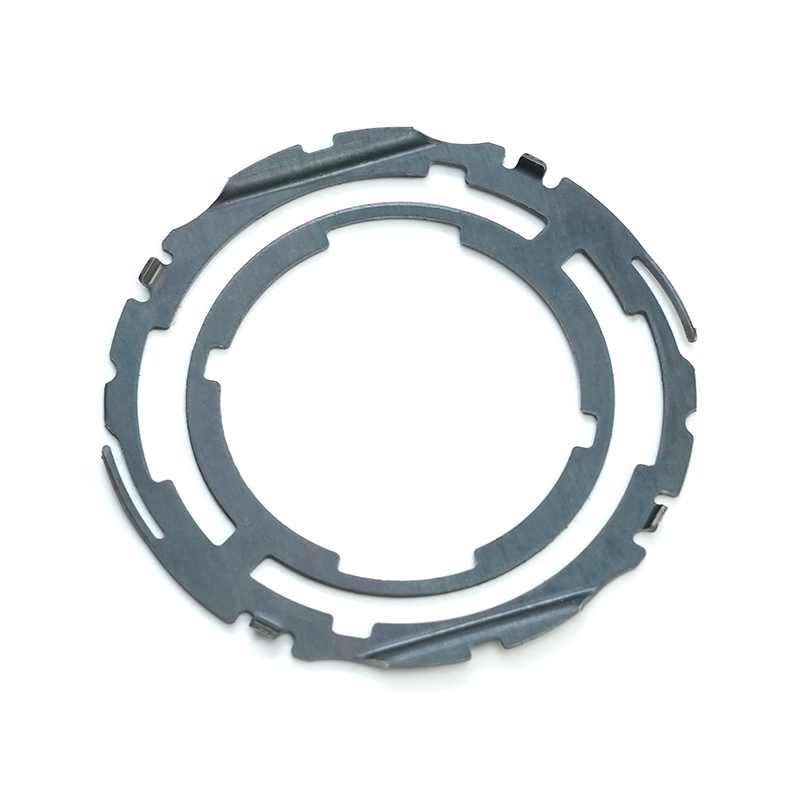

What Are Stainless Steel Stamping Parts?

Stainless steel stamping parts are components created by pressing or stamping stainless steel sheets into specific shapes using dies and presses. These parts are used in industries such as automotive, aerospace, medical, and consumer electronics. The process allows for high precision and repeatability, making it ideal for mass production.

Types of Stainless Steel Used in Stamping

Different grades of stainless steel are used in stamping, depending on the application. Common grades include:

- Austenitic Stainless Steel (e.g., 304, 316): Known for excellent corrosion resistance and formability.

- Ferritic Stainless Steel (e.g., 430): Magnetic and resistant to stress corrosion cracking.

- Martensitic Stainless Steel (e.g., 410): High strength and hardness, often used in cutlery and industrial equipment.

The Stainless Steel Stamping Process

The stamping process involves several steps:

1. Material Selection: Choosing the right stainless steel grade based on the part's requirements.

2. Blanking: Cutting the sheet metal into smaller pieces.

3. Punching: Creating holes or cutouts in the metal.

4. Bending: Forming the metal into the desired shape.

5. Finishing: Applying coatings or polishing for enhanced durability and aesthetics.

Advantages of Stainless Steel Stamping Parts

Stainless steel stamping offers numerous benefits:

- High Precision: Ensures consistent quality across large production runs.

- Cost-Effective: Reduces material waste and labor costs.

- Durability: Stainless steel resists corrosion, heat, and wear.

- Versatility: Suitable for complex geometries and thin-walled components.

Common Applications of Stainless Steel Stamping Parts

These parts are used in:

- Automotive Industry: Brackets, clips, and exhaust components.

- Medical Devices: Surgical instruments and implantable components.

- Electronics: Connectors, shields, and enclosures.

- Construction: Fasteners, hinges, and architectural elements.

Quality Control in Stainless Steel Stamping

Ensuring high-quality stamped parts involves:

- Material Inspection: Verifying the steel grade and thickness.

- Dimensional Checks: Using precision tools to measure tolerances.

- Surface Finish Evaluation: Ensuring no cracks, burrs, or defects.

Challenges in Stainless Steel Stamping

Despite its advantages, stainless steel stamping presents challenges:

- Work Hardening: Stainless steel can become brittle during forming.

- Tool Wear: High-strength steel can accelerate die wear.

- Springback: The material may return slightly to its original shape after stamping.

Future Trends in Stainless Steel Stamping

Emerging trends include:

- Automation: Increased use of robotics for precision and efficiency.

- Advanced Materials: Development of new stainless steel alloys for improved performance.

- Sustainable Practices: Recycling and reducing waste in production.

Conclusion

Stainless steel stamping parts play a crucial role in modern manufacturing, offering durability, precision, and cost savings. Understanding the process, materials, and applications helps industries make informed decisions for their production needs. As technology advances, stainless steel stamping will continue to evolve, meeting the demands of various sectors.