The Advantages of Mass Production Through Automotive Steel Stamping Parts

Automotive steel stamping parts have become an indispensable process in modern vehicle manufacturing, playing a vital role in the production of high-quality, reliable components that form the backbone of cars, trucks, and commercial vehicles. This manufacturing technique involves shaping and forming steel sheets through a stamping press, which performs various operations such as cutting, punching, bending, and deep drawing. Thanks to these processes, steel stamping enables the efficient creation of precise and complex parts that contribute significantly to the structural integrity, safety, and overall performance of vehicles.

One of the most notable advantages of Automotive steel stamping parts is its exceptional capacity for mass production. The automotive industry demands millions of components to be produced with consistent quality and tight tolerances, and steel stamping presses are engineered to operate at high speeds, delivering uniform parts at scale. This high-volume production capability makes steel stamping a cost-effective choice for automakers, reducing manufacturing time and expenses while ensuring the durability and strength necessary for automotive applications.

The choice of materials in Automotive steel stamping parts is a key factor in meeting the demands of mass production without compromising quality. High-strength steels, mild steels, and advanced high-strength steels (AHSS) are widely used due to their ability to withstand significant stress and impact, offering excellent weight-saving properties without sacrificing durability. These materials enable manufacturers to produce parts such as frame members, door panels, roof panels, hoods, fenders, and various interior components including brackets, supports, and reinforcements that collectively ensure the vehicle’s performance and safety.

Steel stamping parts are also crucial to vehicle safety. Many components produced through stamping are engineered to absorb and dissipate energy in the event of collisions, enhancing crashworthiness. Reinforced parts like side-impact beams, bumper reinforcements, and structural supports provide critical protection to passengers by mitigating the forces experienced during accidents. The precision and uniformity achieved in mass-produced stamped parts guarantee that every vehicle meets stringent safety standards, reflecting the process's reliability in producing life-saving components.

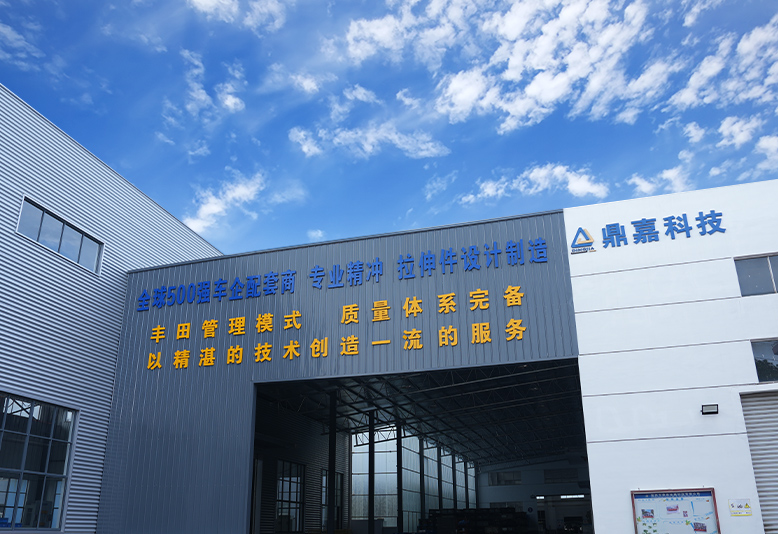

Changzhou Dingjia Metal Technology Co., Ltd. exemplifies the strengths of Automotive steel stamping parts in mass production. Established in 2010 and based in Changzhou City, the company specializes in the design, assembly, and maintenance of precision metal molds as well as the manufacturing of metal stamping parts. Its facilities cover an extensive area with plans for expansion, reflecting the company’s commitment to scaling production capacity. With a registered capital of 19 million yuan and a comprehensive quality management system, Changzhou Dingjia has earned industry recognition for its product quality and integrity.

Serving industries including automotive, electronics, and medical machinery, Changzhou Dingjia’s ability to deliver precision metal stamping parts in large volumes has made it a trusted partner for many well-known enterprises. The company’s focus on maintaining high standards during mass production ensures that each stamped part meets the exact specifications required for critical automotive applications. This reliability is essential in an industry where even the smallest deviation can affect vehicle safety and performance.

The evolution of Automotive steel stamping parts continues to be driven by the need for more lightweight and complex designs that improve fuel efficiency and comply with increasingly strict environmental regulations. Advanced stamping techniques allow manufacturers to integrate these innovations without sacrificing speed or cost efficiency. This ongoing advancement highlights the flexibility of steel stamping as a mass production method, capable of adapting to the changing needs of the automotive market.

The advantages of mass production through Automotive steel stamping parts are multifaceted, encompassing efficiency, cost-effectiveness, precision, and safety. The process’s ability to rapidly produce large quantities of durable, complex parts underpins much of today’s vehicle manufacturing. Companies like Changzhou Dingjia Metal Technology Co., Ltd. demonstrate how expertise and investment in quality systems contribute to the continued success of steel stamping in meeting the automotive industry's rigorous demands. As technology advances and market needs evolve, Automotive steel stamping parts will remain a cornerstone of manufacturing, delivering the components that keep vehicles safe, reliable, and efficient on the road.