Stainless steel stamping parts have become an integral part of numerous industries due to their unique combination of properties. This article delves into the world of stainless steel stamping parts, exploring their manufacturing processes, advantages, applications, and more.

Commonly Cast Stainless Steel Alloys

Stainless steel comes in a variety of alloys, each with its own set of characteristics. The following table shows some of the commonly used stainless steel alloys in stamping:

| Alloy | Characteristics | Applications |

| 304 | Excellent corrosion resistance, good formability | Food industry, architecture, general manufacturing |

| 316 | High corrosion resistance, especially in marine and chemical environments | Marine applications, medical equipment, chemical processing |

| 430 | Good corrosion resistance, magnetic properties | Automotive trim, appliances |

| 210 | Cost-effective, reasonable formability | Decorative applications, some consumer products |

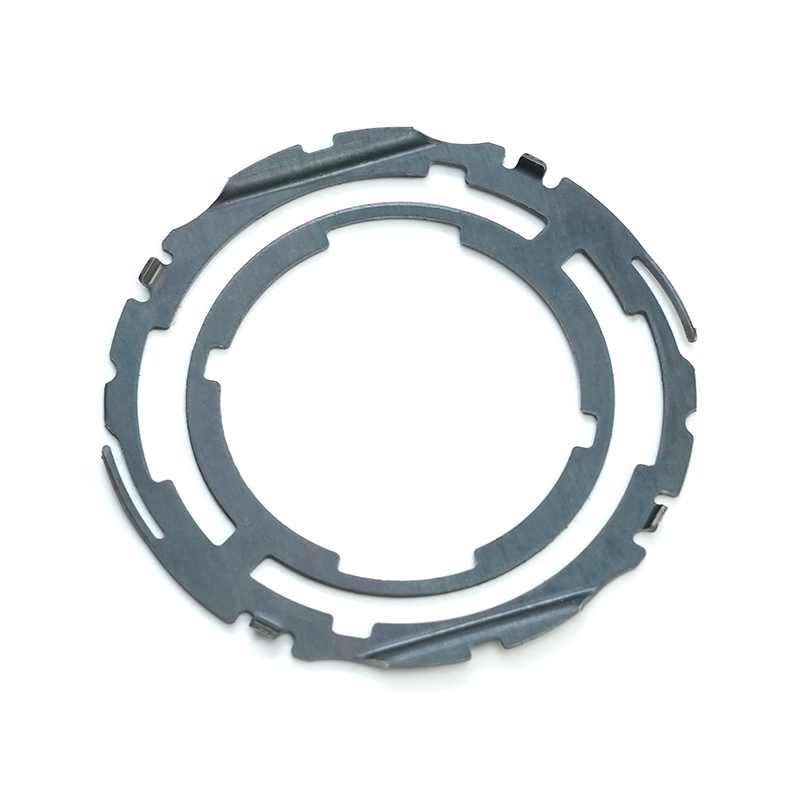

Stainless Steel Stamping Operations

The process of creating stainless steel stamping parts involves several key operations:

Punching

Punching is used to create holes or remove material from the stainless steel sheet. It is a precise operation that can produce holes of various shapes and sizes.

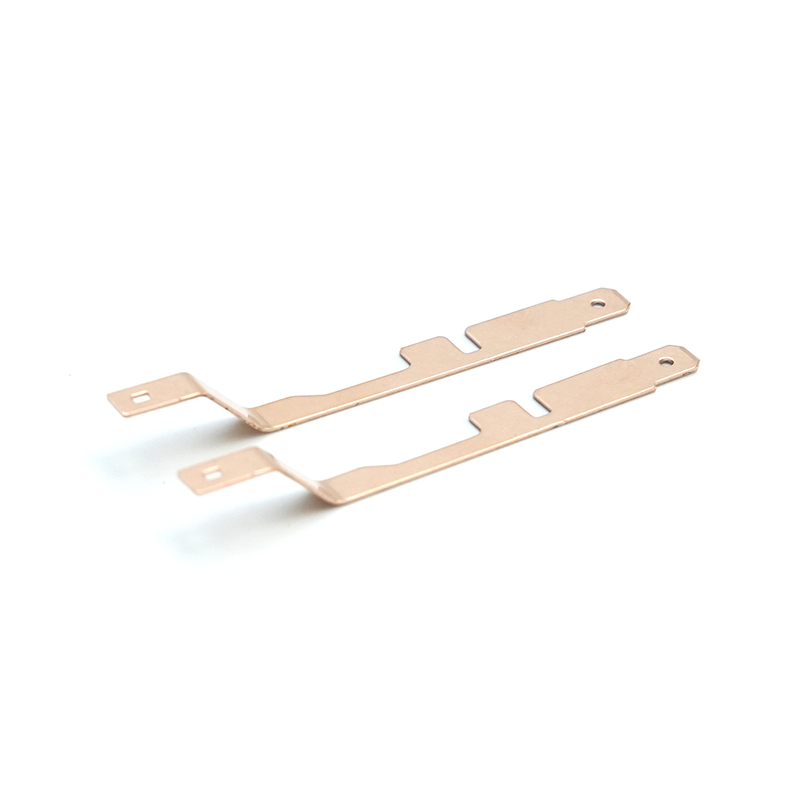

Bending

Bending allows the stainless steel to be shaped into different angles and curves. This operation requires careful control to ensure accurate bends without cracking the material.

Metal Forming

Metal forming encompasses a range of techniques to shape the stainless steel into the desired final form, such as deep drawing to create hollow parts.

Casting (in some cases)

In certain situations, casting may be combined with stamping to achieve complex geometries. However, this is less common compared to the other operations in pure stamping processes.

Advantages of Stainless Steel Stamping Parts

Durability

Stainless steel stamping parts are highly durable and can withstand harsh environments, including high temperatures and corrosive substances.

Strength

They offer high strength, making them suitable for applications that require load-bearing capabilities.

Aesthetic Appeal

Stainless steel has a sleek and modern appearance, which is appealing for both functional and decorative applications.

Resistance to Corrosion

One of the most significant advantages is the excellent corrosion resistance of stainless steel, reducing the need for frequent maintenance and replacement.

Applications of Stainless Steel Stamping Parts

Aerospace Industry

In the aerospace sector, stainless steel stamping parts are used in components such as aircraft engines, landing gear, and interior fittings due to their high strength and corrosion resistance.

Electronics Industry

Stainless steel is used for connectors, enclosures, and heat sinks in electronic devices. Its electrical conductivity and ability to dissipate heat make it a suitable choice.

Medical Field

Stainless steel stamping parts are found in medical equipment like surgical instruments, implants, and diagnostic devices. Their biocompatibility and corrosion resistance are crucial in this industry.

Automotive Industry

Automotive applications include parts such as exhaust systems, brake components, and decorative trim. Stainless steel's durability and strength contribute to the performance and longevity of vehicles.

Food and Beverage Industry

Stainless steel is widely used in food processing equipment, storage tanks, and utensils due to its hygienic properties and resistance to corrosion from food and cleaning agents.

Conclusion

Stainless steel stamping parts play a vital role in a wide range of industries, offering a combination of strength, durability, and corrosion resistance. With advancements in manufacturing technology, the precision and quality of these parts continue to improve, opening up new possibilities for innovative designs and applications. Whether in aerospace, electronics, medical, automotive, or food industries, stainless steel stamping parts are an essential component for reliable and high-performing products.