Copper-Based Plated Stamping Parts are important basic components for improving the conductivity of electronic components

In the rapidly evolving world of electronics, where miniaturization, performance, and reliability are key drivers, the role of high-quality metal components cannot be overstated. Among these, copper-based plated stamping parts have emerged as essential building blocks in enhancing the conductivity and overall efficiency of electronic devices. These precision-engineered components not only ensure stable electrical transmission but also contribute to the longevity and durability of complex systems ranging from consumer electronics to industrial and medical equipment.

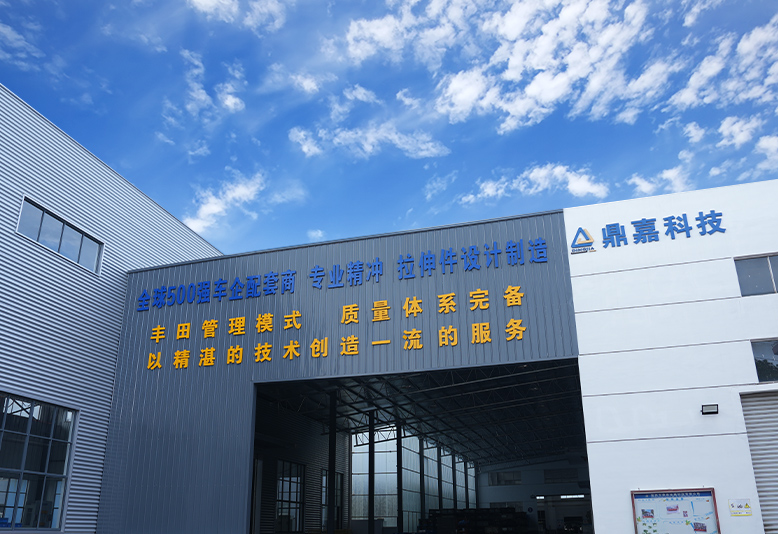

One company that has consistently demonstrated excellence in the production of such critical components is Changzhou Dingjia Metal Technology Co., Ltd. , a private enterprise founded in 2010. Located in Xueyan Town, Wujin District, Changzhou City — just a short distance from the scenic Taihu Lake — the company operates from a modern facility covering 5400 square meters. With plans to expand by an additional 1500 square meters in 2024 and a registered capital of 19 million yuan, Changzhou Dingjia Metal Technology has established itself as a leading player in the design, assembly, and maintenance of precision metal molds, as well as the manufacturing of high-precision stamped metal parts.

The Significance of Copper-Based Plated Stamping Parts

Conductivity is a fundamental requirement in the field of electronics, especially in applications where signal integrity and power transmission are crucial. Copper, known for its excellent electrical and thermal conductivity, serves as an ideal base material for components used in circuitry, connectors, and other conductive elements. However, pure copper may not always meet the mechanical or environmental demands of certain applications. This is where plating technology comes into play.

By plating copper-based materials with metals such as nickel, tin, silver, or gold, manufacturers can significantly enhance corrosion resistance, improve solderability, increase wear resistance, and maintain optimal conductivity. These copper-based plated stamping parts are widely used in:

Automotive electronics : From sensors to control units, reliable conductivity ensures vehicle safety and performance.

Consumer electronics : Smartphones, laptops, and wearable devices rely on micro-components that must function flawlessly under compact designs.

Medical equipment : Precision instruments demand high-reliability components to ensure patient safety and accurate diagnostics.

Industrial automation : Control panels, switches, and relays require durable and conductive parts to maintain operational continuity.

Changzhou Dingjia Metal Technology: A Trusted Partner in Precision Manufacturing

At the heart of Changzhou Dingjia Metal Technology’s success lies its commitment to quality, innovation, and customer satisfaction. The company specializes in the production of precision metal stamping parts , with a particular focus on those made from copper alloys and plated surfaces. Its state-of-the-art manufacturing capabilities include advanced stamping machines, CNC machining centers, and automated plating lines that ensure consistency, accuracy, and high throughput.

The company's expertise in mold design and development allows it to customize products according to client specifications, ensuring that each component meets the exact dimensional and functional requirements of its intended application. Moreover, Changzhou Dingjia Metal Technology adheres to a comprehensive quality management system , which has earned the company widespread recognition and trust within the industry.

Over the years, the company has forged strategic partnerships with numerous well-known enterprises across various sectors, including automotive, electronics, and medical machinery. These collaborations are a testament to the company's ability to deliver high-performance solutions that align with global standards and evolving technological needs.

How Copper-Based Plated Stamping Parts Improve Conductivity

To understand why copper-based plated stamping parts are so vital for improving conductivity, it’s important to break down their properties and functions:

1. Superior Electrical Conductivity

Copper ranks second only to silver in terms of electrical conductivity among commonly available metals. When used as a base material in stamping parts, it enables efficient electron flow, minimizing energy loss and heat generation. This is particularly important in high-frequency circuits and power transmission systems.

2. Enhanced Surface Properties Through Plating

While copper offers excellent conductivity, it can oxidize or corrode over time when exposed to moisture or harsh environments. By applying protective plating layers — such as nickel for hardness and corrosion resistance, or gold for superior conductivity and oxidation protection — the lifespan and reliability of the component are significantly improved.

3. Precision Engineering for Miniaturization

Modern electronics continue to trend toward smaller, more powerful devices. Copper-based stamped parts, manufactured using advanced tooling and precision stamping techniques, allow for intricate shapes and ultra-thin profiles without compromising conductivity or structural integrity.

4. Cost-Effective Performance

Compared to alternatives like pure silver or gold-plated components, copper-based plated parts offer a cost-effective solution that maintains high performance. This makes them ideal for mass production in industries where both budget constraints and performance expectations are high.

Applications Across Industries

Automotive Electronics

With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the demand for high-conductivity components has surged. Copper-based stamped connectors, terminals, and relay contacts are extensively used in vehicle control modules, battery management systems, and onboard charging units. Changzhou Dingjia Metal Technology plays a pivotal role in supplying these critical components to tier-one automotive suppliers.

Consumer Electronics

Smartphones, tablets, and wearable tech require tiny yet robust components capable of handling high-speed data transfer and power delivery. Copper-plated stamping parts serve as contact points in micro-connectors, flex circuits, and internal wiring harnesses, ensuring seamless device operation.

Medical Equipment

In life-saving devices such as MRI machines, pacemakers, and diagnostic tools, even minor fluctuations in conductivity can have serious consequences. Copper-based stamped parts with biocompatible plating options provide the necessary stability and safety required in such critical applications.

Industrial Automation

From programmable logic controllers (PLCs) to motor drives and switchgear, industrial systems depend heavily on reliable electrical connections. Copper-based stamped components help maintain consistent conductivity in demanding environments characterized by vibration, temperature extremes, and chemical exposure.

Quality Assurance at Changzhou Dingjia Metal Technology

Quality is non-negotiable when it comes to electronic components, especially those involved in critical systems. Changzhou Dingjia Metal Technology has implemented rigorous quality control measures throughout its production process, including:

Raw material inspection : Ensuring all incoming copper and alloy materials meet international standards.

In-process testing : Monitoring dimensions, plating thickness, and conductivity during manufacturing.

Final product verification : Conducting electrical tests, salt spray tests, and tensile strength analysis before shipment.

These practices not only guarantee product reliability but also support compliance with international certifications and industry-specific regulations.

Copper-based plated stamping parts are indispensable in the realm of modern electronics, offering a perfect blend of conductivity, durability, and cost-efficiency. As a trusted manufacturer in this domain, Changzhou Dingjia Metal Technology Co., Ltd. stands out for its technical expertise, commitment to quality, and strategic vision. Whether supporting the next-generation electric car or life-saving medical devices, the company continues to drive innovation and excellence in the production of precision metal components that power the future.