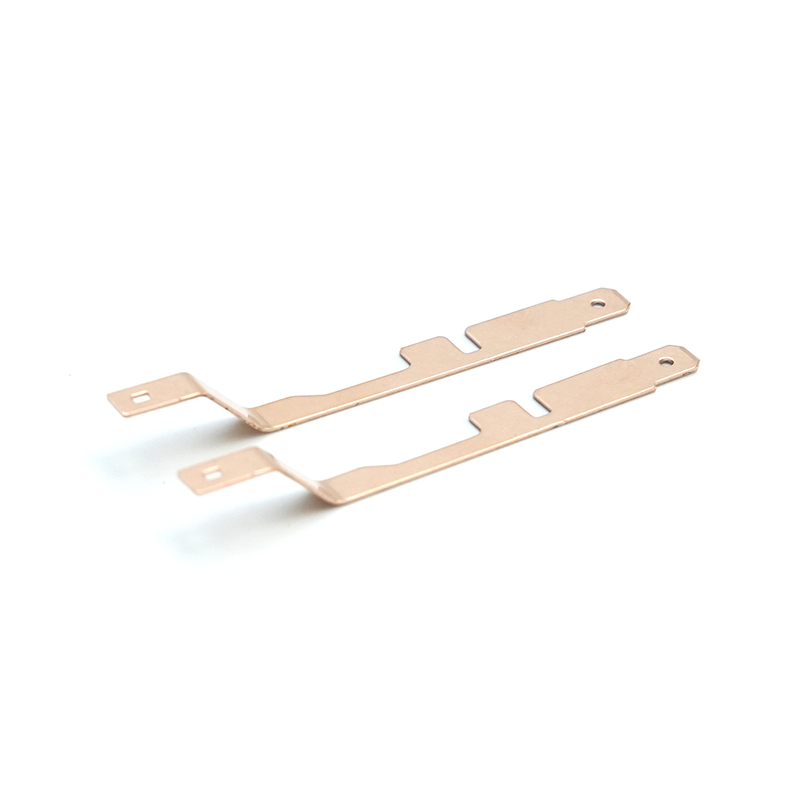

Phosphor Bronze Connector

contact

Phosphor bronze connectors are precision-engineered electrical components made from a copper alloy that combines copper, tin, and phosphorus. This specialized material offers a unique blend of electrical conductivity, corrosion resistance, and mechanical properties, making it ideal for high-performance applications across various industries.

Key Features:

High Electrical Conductivity: Phosphor bronze is known for its conductivity, making it an ideal material for connectors that need to transmit electrical signals efficiently with minimal energy loss.

Corrosion Resistance: The tin content in phosphor bronze provides resistance to oxidation and corrosion, ensuring reliable performance in harsh environments. This makes it a great choice for outdoor and industrial applications, where connectors are exposed to moisture, chemicals, and temperature fluctuations.

Durability and Strength: The alloy’s unique composition offers strength and resistance to wear and tear. Phosphor bronze connectors maintain their shape and functionality even under mechanical stress, vibration, or high current loads.

Fatigue Resistance: Phosphor bronze has outstanding fatigue resistance, meaning the connectors can withstand repeated flexing or vibrations without failing, making them suitable for applications in automotive, aerospace, and industrial machinery.

Versatility: Available in a variety of shapes and sizes, phosphor bronze connectors can be customized for different uses, from simple electrical connections to complex, high-density circuits. They are often used in electronic devices, automotive systems, telecommunications equipment, and power distribution networks.

Temperature Stability: The material’s performance is stable across a wide temperature range, maintaining conductivity and mechanical properties even in conditions, making it highly reliable for both low and high-temperature applications.

Applications: Phosphor bronze connectors are widely used in industries such as automotive, telecommunications, electronics, aerospace, and electrical power systems, offering long-lasting performance in critical systems where reliability is paramount.

Phosphor bronze connectors are a trusted solution for applications requiring high reliability, durability, and electrical performance.