Copper Stamping Parts Assembly and Use Effect in Industrial Equipment

Copper stamping parts play a crucial role in modern industrial equipment due to their excellent electrical conductivity, thermal performance, corrosion resistance, and malleability. These properties make them ideal for use in electronics, automotive systems, medical machinery, and various other high-precision manufacturing fields. As industries continue to demand higher performance and reliability from their components, the importance of precision-engineered copper stamping parts has never been greater.

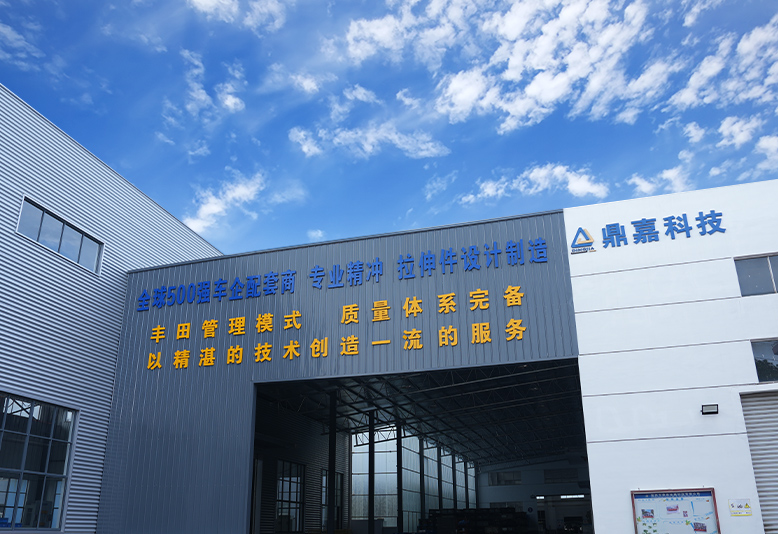

At the forefront of this evolving industry is Changzhou Dingjia Metal Technology Co., Ltd. , a privately-owned enterprise established in 2010. The company specializes in the design, assembly, and maintenance of precision metal molds, as well as the production of high-quality stamped metal components. With its headquarters located in Xueyan Town, Wujin District, Changzhou City—near the scenic Taihu Lake—Changzhou Dingjia benefits from a strategic location that supports efficient logistics and timely delivery. It is approximately 220 kilometers from Shanghai Pudong International Airport and just 59 kilometers from Changzhou Benniu International Airport.

The company currently operates out of a 5,400 square meter facility, with plans to expand by an additional 1,500 square meters in 2024. Backed by a registered capital of 19 million yuan, Changzhou Dingjia continues to invest in advanced production technologies and quality control systems. Its commitment to excellence has earned it a strong reputation and long-term partnerships with numerous well-known enterprises across multiple industries.

Advanced Production of Copper Stamping Parts

Copper stamping involves a series of precise forming and cutting processes using specialized dies and presses. At Changzhou Dingjia, the production line integrates advanced CNC machining, high-precision stamping equipment, and automated systems to ensure consistent part accuracy and surface finish. The technical team works closely with clients to understand their specific application needs, enabling customized solutions that optimize both functionality and durability.

Assembly plays a vital role in determining the final performance of Copper Stamp in industrial equipment. Whether used as connectors, terminals, heat sinks, or shielding components, these parts must be precisely aligned and securely fastened to ensure reliable operation under demanding conditions. Changzhou Dingjia employs strict quality control procedures throughout the assembly process, including dimensional inspection, material testing, and functional verification, ensuring every component meets or exceeds customer expectations.

Applications Across Key Industries

In the automotive sector, copper stamping parts are widely used in electrical systems, sensors, and power transmission components. Their high conductivity and thermal stability contribute to the overall efficiency and safety of vehicles. In electronics, these parts serve as critical elements in circuit boards, connectors, and switches, where precision and reliability are essential. Meanwhile, in the medical field, copper stamping parts support the development of high-precision diagnostic and treatment equipment, ensuring stable performance and long service life.

Beyond these applications, copper stamping parts also find extensive use in heavy industrial machinery, energy systems, and automation equipment. Their ability to withstand harsh environments while maintaining structural integrity makes them indispensable in high-demand settings.

Commitment to Quality and Innovation

Changzhou Dingjia Metal Technology Co., Ltd. adheres to a comprehensive quality management system that covers every stage of production—from raw material selection to final product inspection. This rigorous approach ensures compliance with international standards and industry-specific requirements. Moreover, the company continuously invests in research and development to stay ahead of technological advancements and meet the ever-changing needs of global markets.

By combining advanced manufacturing capabilities with a customer-centric philosophy, Changzhou Dingjia has established itself as a trusted partner for businesses seeking high-quality copper stamping solutions. Its dedication to innovation, precision, and reliability not only enhances the performance of industrial equipment but also contributes to the advancement of key manufacturing sectors worldwide.

As industrial technology continues to evolve, the demand for superior copper stamping parts will only increase. Companies like Changzhou Dingjia are playing a pivotal role in shaping the future of industrial component manufacturing, ensuring that today’s equipment remains efficient, durable, and ready for tomorrow’s challenges.