How Iron Stamping Parts Are Manufactured: Techniques and Advantages

Iron stamping parts play a vital role in many industries, from automotive to electronics and medical machinery. These components are produced through a specialized stamping process that shapes and cuts sheet iron using high-pressure tools and dies. Understanding the manufacturing techniques and benefits of iron stamping parts can help businesses select the right supplier and ensure quality in their production lines.

Manufacturing Techniques of Iron Stamping Parts

The core of iron stamping lies in converting flat sheets of iron into precise, functional parts. This is achieved by placing the sheet metal into a stamping press, where a die applies significant pressure to form the desired shape. The process includes multiple techniques such as punching, bending, deep drawing, and embossing. Each method contributes to the ability to create complex and detailed parts that meet specific industrial needs.

Punching involves cutting holes or shapes out of the sheet metal.

Bending changes the metal’s shape by deforming it along a straight axis.

Deep drawing pulls the metal sheet into a mold to form hollow or concave shapes.

Embossing adds raised or recessed designs on the surface for functional or aesthetic purposes.

These techniques enable mass production of iron stamping parts with consistent precision and quality, which is critical for industries requiring uniform components.

Advantages of Iron Stamping Parts

One of the primary benefits of iron stamping is its cost-effectiveness. The process is highly efficient for producing large volumes, significantly reducing the per-unit cost compared to other manufacturing methods. Additionally, the use of specialized dies ensures that each stamped part is identical, minimizing variability and the need for secondary processing.

Iron itself is a strong and durable material, making stamped parts suitable for applications that demand mechanical resilience and exposure to challenging environments. The precision and reliability of iron stamping parts contribute to better product performance, whether used as vehicle body panels, electronic housings, or medical device components.

About Changzhou Dingjia Metal Technology Co., Ltd.

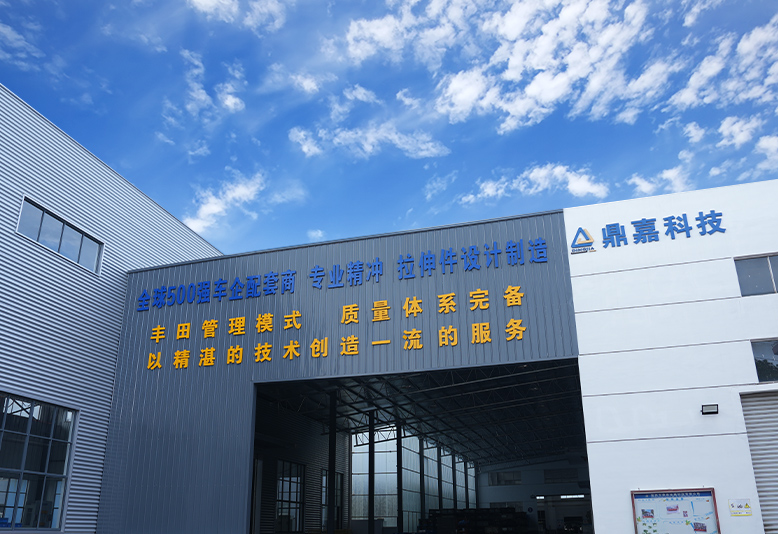

Established in 2010, Changzhou Dingjia Metal Technology Co., Ltd. specializes in the design, assembly, and maintenance of precision metal molds and the manufacturing of iron stamping parts. Located in Xueyan Town, Wujin District, Changzhou City, the company benefits from a strategic position near Taihu Lake and within reach of major transport hubs, including Shanghai Pudong Airport and Changzhou Benniu International Airport.

Covering an area of 5400 square meters with an additional 1500 square meters planned for 2024, the facility is well-equipped to support large-scale production. With a registered capital of 19 million yuan, Dingjia Metal maintains a comprehensive quality management system recognized within the industry for integrity and consistent product quality.

Industry Applications and Partnerships

Changzhou Dingjia Metal Technology’s iron stamping parts serve a variety of sectors including automotive, electronics, and medical machinery. Their components are used in vehicle structural parts, electrical device enclosures, and precision instruments, among others. The company has established partnerships with many well-known enterprises, reflecting its capability to meet demanding standards and provide reliable supply.

The manufacturing of iron stamping parts involves a combination of advanced stamping techniques and quality materials that together offer precision, durability, and cost efficiency. Companies like Changzhou Dingjia Metal Technology Co., Ltd. demonstrate how expertise in mold design and metal stamping can produce high-quality parts tailored to diverse industrial applications. Understanding these manufacturing processes and advantages helps businesses make informed decisions when selecting iron stamping parts suppliers.