Understanding Precision Stamping Parts in Modern Manufacturing

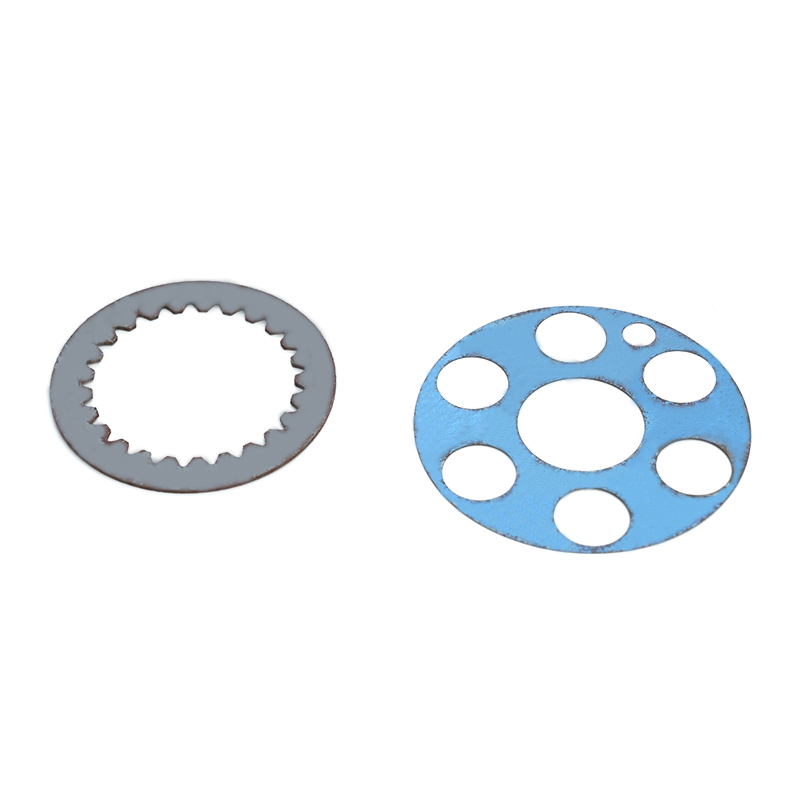

Precision stamping parts are metal components produced by cutting and forming sheet material using dies and presses. Unlike basic stamping, precision stamping focuses on high tolerances, repeatability, and achieving complex geometries with tight specifications. Precision stamped components appear in aerospace assemblies, medical devices, automotive sensor housings, and electronics chassis where dimensional accuracy and consistent performance are non‑negotiable.

The core intent of precision stamping is to transform flat metal sheets into useful parts with minimal secondary operations. This saves manufacturing time, lowers costs, and ensures consistent part quality across production runs. Precision stamping is not a broad term; it specifically refers to high‑accuracy processes rather than generic punching or blanking.

Key Materials Used for Precision Stamping Parts

Choosing the right material directly affects part performance, stamping tolerance, and overall production cost. Precision stamping can be applied to ferrous and non‑ferrous metals, each selected based on mechanical properties and end‑use requirements.

Common Metals in Precision Stamping

- Stainless Steel – Excellent corrosion resistance and strength for medical and food‑grade parts.

- Cold‑Rolled Steel – Good flatness and surface finish, ideal for structural stamped components.

- Aluminum Alloys – Lightweight and thermally conductive, used in automotive and electronics housings.

- Copper Alloys – High electrical conductivity for connectors and terminals.

Precision Stamping Tooling: Design and Maintenance

Tooling is the backbone of precision stamping. The design, material selection, and maintenance of dies determine the achievable tolerances and part quality. Proper tooling reduces variability and supports high‑volume production without frequent downtime.

Design Considerations for Stamping Dies

- Tolerance Requirements: Dies must be machined to tighter tolerances than the final part to account for springback and material flow.

- Material Hardness: Die steels with appropriate hardness levels resist wear and extend life.

- Lubrication Strategy: Designed channels and pockets help control friction, reduce wear, and improve part surface quality.

- Modularity: Modular die components lower fixture changeover time and support part variation.

Routine Tooling Maintenance Practices

Implementing a regular maintenance schedule prevents unexpected downtime and ensures consistent part quality. Typical maintenance tasks include cleaning dies, checking alignment, sharpening edges, and measuring wear points. Keeping detailed tooling logs allows manufacturers to predict when a die needs refurbishment before defects occur.

Precision Stamping Process: From Design to Production

A controlled process flow ensures that each precision stamping part meets design specifications and complies with industry standards. Below are the key phases in practical terms:

1. Engineering Design and Simulation

During design, engineers use CAD and finite element analysis (FEA) to optimize part geometry, select materials, and simulate forming behavior. Simulation identifies potential issues like cracks or excessive thinning before physical tooling.

2. Die Fabrication and Trial Runs

Once design is finalized, precision dies are fabricated using CNC machining and EDM processes. A trial run with actual materials verifies fit, dimensional tolerances, and process repeatability. Adjustments are recorded and re‑tested until the process is stable.

3. Production and In‑Process Inspection

High volumes are typical in precision stamping. Inline inspection methods—such as laser measurement and vision systems—monitor parts in real time. Quality checks are integrated at regular intervals to catch deviations early and reduce scrap rates.

Common Applications and Performance Requirements

Precision stamping parts are essential in markets where dimensional accuracy and dependable performance are critical. Below we show specific industries and how their requirements guide precision stamping practices.

| Industry | Typical Components | Performance Needs |

| Automotive | Sensor brackets, EMI shields | High durability, tight dimensional control |

| Medical Devices | Implant retainers, surgical instrument parts | Biocompatibility, precision surface finish |

| Electronics | Connector terminals, shielding components | Electrical conductivity, micron‑level tolerances |

Quality Assurance and Tolerance Control

Precision stamping requires rigorous quality assurance (QA) methods to ensure each part meets specifications. QA practices are not vague inspections; they target key measurable attributes of parts and processes.

Critical Inspection Techniques

- Coordinate Measuring Machines (CMM): Verify 3D dimensions with micron‑level accuracy.

- Optical Comparators: Check profiles and feature alignment without contact.

- Laser Micrometers: Measure diameters and part thickness inline.

- Statistical Process Control (SPC): Track trends over time to reduce variation and identify process drift.

Cost Optimization Strategies for Precision Stamping

Cost optimization in precision stamping is achievable without compromising quality. Focused improvements in material utilization, die life, and production throughput lower unit costs and enhance competitiveness.

Practical Methods to Reduce Costs

- Optimize blank nesting to minimize material waste.

- Invest in durable die materials to extend tool life and reduce changeovers.

- Use progressive dies to consolidate multiple operations into one pass.

- Apply predictive maintenance to avoid unexpected press downtime.

By keeping process data, tooling performance logs, and part inspection results organized, manufacturers can identify bottlenecks and prioritize continuous improvements that produce measurable value.