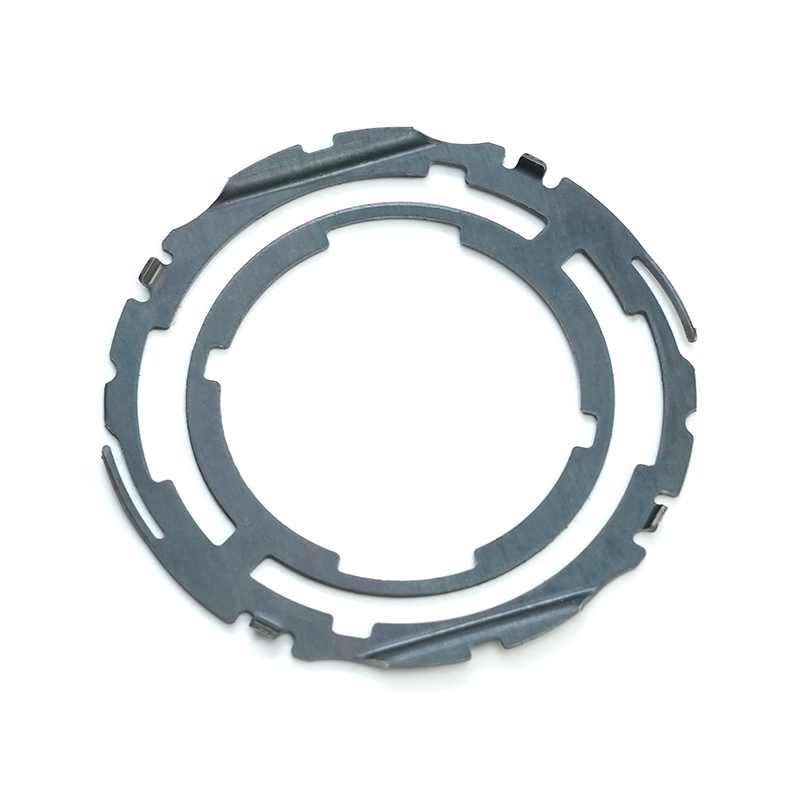

Understanding Stainless Steel Stamping Parts

Stainless steel stamping parts are essential components in industries ranging from automotive to electronics. These parts are produced by deforming stainless steel sheets into precise shapes through stamping processes. Understanding the properties and advantages of stainless steel is crucial for ensuring durability, corrosion resistance, and long-term performance of stamped components.

Materials and Grades Used in Stamping

Selecting the appropriate stainless steel grade is vital for achieving desired performance in stamped parts. The most common grades include:

- 304 Stainless Steel: Excellent corrosion resistance, suitable for general-purpose parts.

- 316 Stainless Steel: Superior corrosion resistance, ideal for marine or chemical environments.

- 430 Stainless Steel: Magnetic and cost-effective, used in appliances and automotive trim.

The choice of material affects not only corrosion resistance but also machinability, formability, and surface finish quality during stamping.

Common Stamping Processes

Stainless steel stamping involves several key processes, each tailored to specific design requirements:

Blanking

Blanking is the process of cutting flat shapes from stainless steel sheets. It is critical for minimizing material waste and achieving precise dimensions for further forming operations.

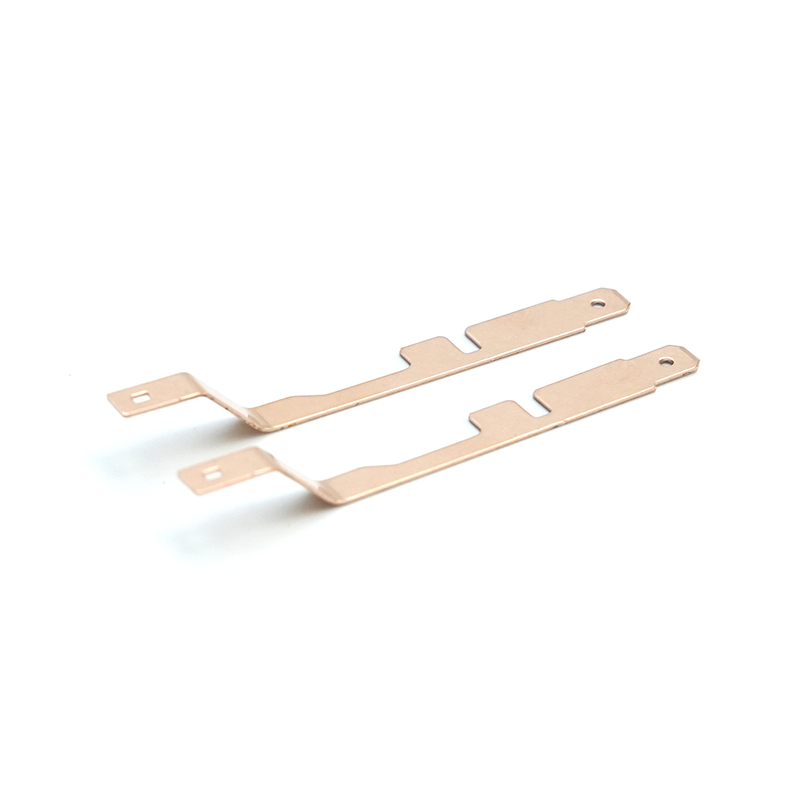

Bending

Bending is used to create angles and complex geometries without removing material. Accurate bending ensures consistent assembly fit and structural integrity.

Deep Drawing

Deep drawing transforms flat stainless steel sheets into cup-shaped or tubular parts. Proper lubrication and die design are critical to prevent tearing and wrinkling of the material.

Progressive Stamping

Progressive stamping allows multiple operations to be performed on a part in a single pass through a die. This method increases production efficiency while maintaining tight tolerances.

Design Considerations for Stamping Parts

Proper design of stainless steel stamping parts is essential to avoid defects and reduce manufacturing costs. Key considerations include:

- Wall Thickness: Maintain uniform thickness to prevent warping during stamping.

- Corner Radii: Avoid sharp corners to reduce the risk of cracking during bending or drawing.

- Tolerances: Specify achievable tolerances based on the stamping process and material springback.

- Surface Finish: Consider post-stamping processes such as polishing or passivation for aesthetic or functional purposes.

Quality Control in Stainless Steel Stamping

Ensuring consistent quality is critical in stainless steel stamping. Effective quality control strategies include:

- Dimensional Inspection: Using calipers, CMM machines, or laser scanning to verify part dimensions.

- Surface Examination: Checking for scratches, burrs, or corrosion spots after stamping.

- Material Testing: Confirming stainless steel grade, hardness, and tensile strength meet specifications.

Documenting and monitoring these quality checkpoints ensures repeatable production and reduces the likelihood of part failures in end-use applications.

Applications of Stainless Steel Stamping Parts

Stainless steel stamped components are widely used due to their strength, corrosion resistance, and precision. Typical applications include:

| Automotive Industry | Brackets, chassis components, and trim parts |

| Electronics | Housings, connectors, and shielding parts |

| Appliances | Panels, fasteners, and support frames |

| Medical Equipment | Instrument components and surgical tools |

Maintenance and Longevity of Stamped Parts

Proper maintenance can extend the service life of stainless steel stamped parts. Recommendations include:

- Regular Cleaning: Remove debris and contaminants using mild detergents or specialized stainless steel cleaners.

- Preventing Galvanic Corrosion: Avoid direct contact with dissimilar metals in corrosive environments.

- Inspection for Wear: Periodically check high-stress components for signs of fatigue or deformation.

By following these practices, stamped stainless steel parts can maintain structural integrity and appearance over extended periods.

Conclusion

Stainless steel stamping parts are critical for modern manufacturing, offering durability, precision, and corrosion resistance. Understanding material selection, stamping processes, design considerations, and quality control can greatly improve production efficiency and component performance. By applying these insights, engineers and manufacturers can create reliable stamped parts tailored for their specific applications.