Introduction to Aluminum Alloy Stamping Parts

Aluminum alloy stamping parts play a crucial role in modern manufacturing due to their lightweight, strength, and corrosion resistance. These components are widely used in automotive, aerospace, electronics, and construction industries. Understanding the materials, processes, and applications is essential for engineers and manufacturers aiming for high precision and reliability.

Common Aluminum Alloys Used for Stamping

Different aluminum alloys offer varying mechanical properties, making them suitable for specific stamping applications. The most frequently used alloys include 5052, 6061, and 7075. Choosing the right alloy impacts the strength, formability, and corrosion resistance of the finished part.

5052 Aluminum Alloy

5052 aluminum is highly resistant to corrosion, particularly in marine environments. It offers good formability, making it suitable for complex stamping operations. Typical applications include automotive body panels, fuel tanks, and electronic enclosures.

6061 Aluminum Alloy

6061 aluminum provides a balance of strength and workability. It is often used in structural components where moderate weight reduction and durability are required. Common uses include aircraft components, machinery frames, and bicycle parts.

7075 Aluminum Alloy

7075 aluminum is a high-strength alloy ideal for parts that require superior mechanical performance. While harder to form, it is frequently employed in aerospace components, high-performance automotive parts, and precision instruments.

Key Stamping Processes for Aluminum Alloys

Stamping aluminum alloys involves shaping sheet metal using dies and presses. The choice of stamping method affects precision, surface quality, and production efficiency. Key processes include blanking, deep drawing, bending, and coining.

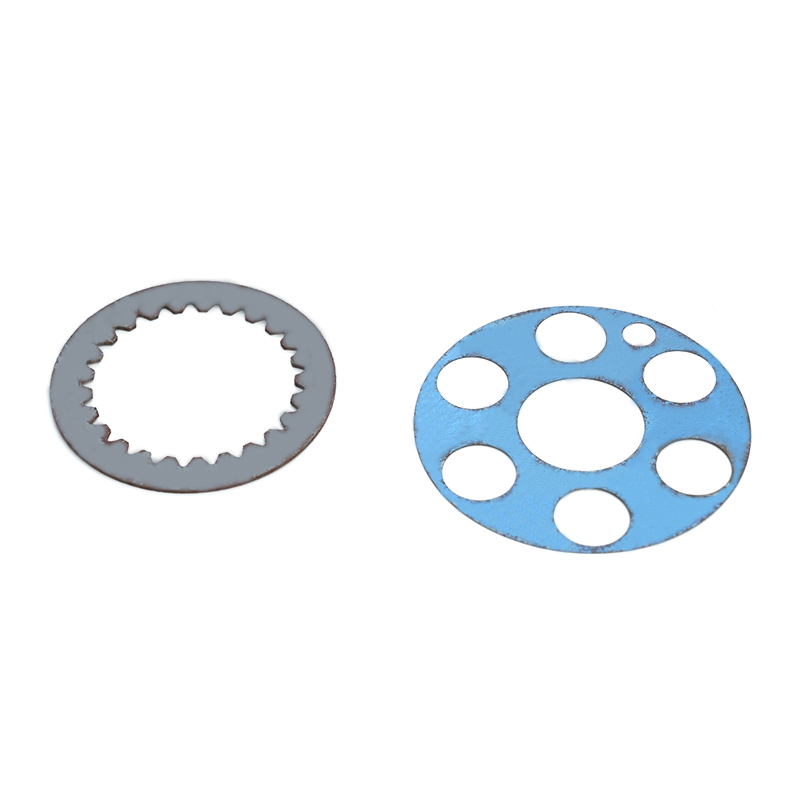

Blanking and Piercing

Blanking removes flat pieces from a sheet, while piercing creates holes or cutouts. Both operations require precise die alignment and proper lubrication to prevent scratches and cracks on the aluminum surface.

Deep Drawing

Deep drawing is used to form cup-shaped or complex 3D parts. Aluminum alloys must be carefully selected for their drawability, and process parameters like punch speed and blank holder force must be optimized to avoid wrinkling or tearing.

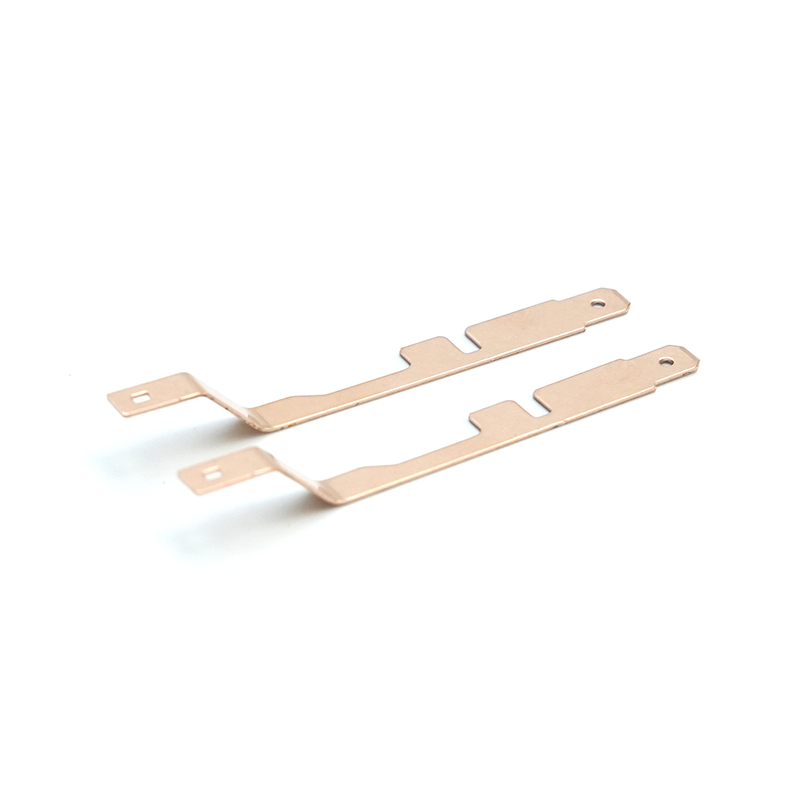

Bending and Coining

Bending shapes aluminum sheets into angles or curves, while coining produces fine details and embossed features. Controlling spring-back and die clearance is essential to achieve precise dimensions.

Surface Finishing and Treatment

After stamping, aluminum parts often require surface treatment to improve corrosion resistance and appearance. Common methods include anodizing, powder coating, and mechanical polishing.

Anodizing

Anodizing enhances corrosion resistance and allows coloring of aluminum surfaces. It is particularly useful for parts exposed to outdoor environments or aesthetic requirements.

Powder Coating

Powder coating provides a durable, uniform finish that resists scratches and UV damage. It is commonly applied in automotive components, electronics housings, and decorative items.

Quality Control in Aluminum Alloy Stamping

Ensuring consistent quality in stamping operations is critical. Dimensional accuracy, surface integrity, and mechanical properties must be verified through systematic inspections and testing.

Dimensional Inspection

Using tools such as calipers, coordinate measuring machines (CMM), and optical scanners, manufacturers verify that stamped parts meet design specifications. Tolerances must be strictly controlled to avoid assembly issues.

Surface and Structural Testing

Visual inspections, dye penetrant tests, and ultrasonic testing help identify surface defects, cracks, or internal voids. Proper detection prevents failures in critical applications.

Applications of Aluminum Alloy Stamping Parts

Aluminum alloy stamping parts are widely applied across industries due to their lightweight and durable properties. Key applications include:

- Automotive components such as engine brackets, body panels, and heat sinks

- Aerospace parts including structural frames and interior panels

- Consumer electronics enclosures and heat-dissipating parts

- Construction elements like window frames, facades, and decorative panels

Comparison of Aluminum Alloys for Stamping

| Alloy | Strength | Formability | Corrosion Resistance | Typical Applications |

| 5052 | Medium | High | Excellent | Automotive panels, fuel tanks, enclosures |

| 6061 | High | Medium | Good | Aerospace components, machinery frames |

| 7075 | Very High | Low | Moderate | Aerospace, high-performance automotive parts |

Conclusion

Aluminum alloy stamping parts are indispensable in modern manufacturing due to their lightweight, durability, and adaptability. By carefully selecting alloys, optimizing stamping processes, and implementing thorough quality control, manufacturers can produce components that meet stringent performance requirements while maintaining efficiency and cost-effectiveness.