Stainless steel stamping parts, aluminum components, and plastic parts are three of the most commonly used materials in modern manufacturing. Each offers unique advantages and disadvantages depending on application, cost, performance, and design requirements. Understanding the distinctions among these materials can help engineers, designers, and manufacturers select the most appropriate material for their projects.

Material Strength and Mechanical Performance

One of the primary considerations in selecting materials is their mechanical strength.

Stainless Steel:

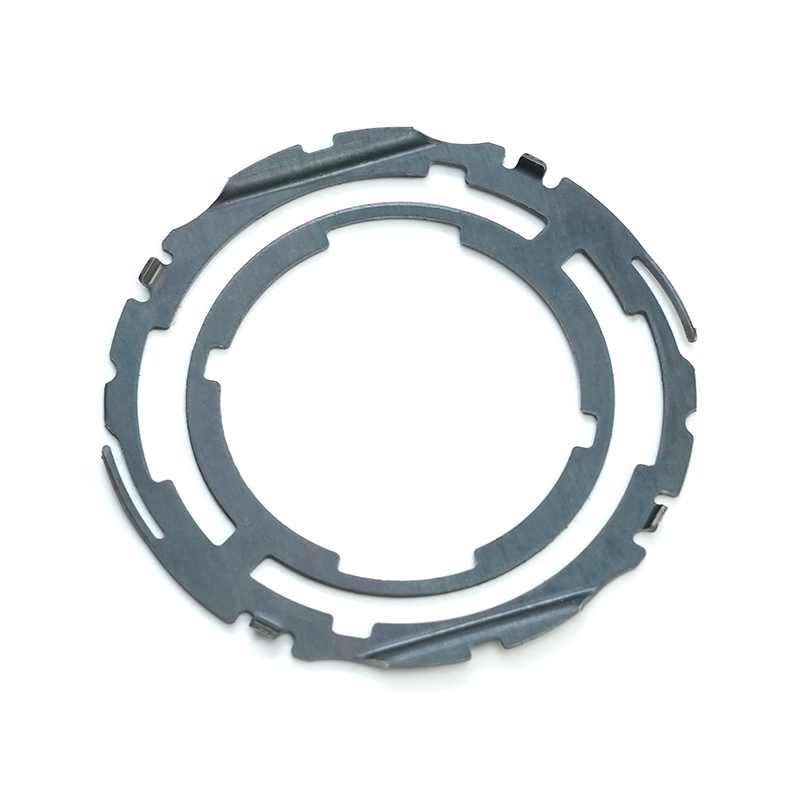

Stainless steel stamping parts are renowned for their high tensile strength and excellent fatigue resistance. They can withstand heavy loads, high pressure, and repeated stress without deforming or failing. This makes stainless steel ideal for applications where structural integrity is critical, such as automotive frames, industrial machinery, and construction hardware.

Aluminum:

Aluminum offers moderate strength, which is lower than that of stainless steel. However, aluminum is highly suitable for applications where a combination of strength and lightweight is desired, such as aerospace and transportation components. Though not as strong as stainless steel, modern aluminum alloys can be engineered to provide impressive performance for many applications.

Plastic:

Plastic components are generally weaker than both stainless steel and aluminum. They are prone to deformation under high loads or long-term stress, though engineering plastics, such as polycarbonate or nylon, can offer improved mechanical performance. Plastics are best suited for applications where structural loads are minimal, and flexibility or insulation is more important.

Weight Considerations

Weight often plays a critical role in manufacturing decisions, especially in automotive, aerospace, and portable devices.

Stainless Steel:

Stainless steel is dense and heavy, which can be a disadvantage in applications where weight reduction is important. However, its high strength-to-weight ratio can offset this in structural applications where durability is essential.

Aluminum:

Aluminum is much lighter than stainless steel, often weighing about one-third as much. Its low density makes it ideal for applications where weight savings improve energy efficiency, performance, or ease of handling.

Plastic:

Plastic is the lightest of the three materials, often dramatically reducing the overall weight of components. Lightweight plastic parts are widely used in consumer electronics, packaging, and automotive interiors.

Corrosion Resistance

Corrosion resistance is a vital consideration for parts exposed to moisture, chemicals, or harsh environments.

Stainless Steel:

Stainless steel is highly resistant to corrosion, rust, and staining due to the presence of chromium, which forms a passive oxide layer on the surface. This makes stainless steel stamping parts suitable for outdoor, marine, and food-processing applications.

Aluminum:

Aluminum naturally forms a thin oxide layer that provides moderate corrosion resistance. However, it is more susceptible to certain types of corrosion, such as pitting, when exposed to saline or acidic environments. Protective coatings or anodizing can improve aluminum’s corrosion resistance.

Plastic:

Plastics are inherently corrosion-resistant and do not rust. They can resist many chemical exposures that would degrade metals. However, UV light and environmental stress cracking can affect some plastics over time.

Cost Comparison

Cost is often a decisive factor in material selection.

Stainless Steel:

Stainless steel is generally more expensive than aluminum and most plastics, both in terms of raw material cost and processing. Its strength and durability, however, often justify the higher cost in critical applications.

Aluminum:

Aluminum tends to be less expensive than stainless steel but more costly than standard plastics. Its moderate price, combined with lightweight properties, makes it cost-effective for many engineering applications.

Plastic:

Plastic is usually the least expensive option, particularly for high-volume production. Injection molding and other plastic forming processes allow mass production at low cost, making plastic suitable for consumer goods and disposable components.

Manufacturability and Stamping Considerations

The manufacturing process can influence both cost and design flexibility.

Stainless Steel:

Stamping stainless steel requires high-quality dies and precise control because the material is hard and resistant to deformation. Stainless steel can maintain tight tolerances and complex geometries, but it may require more energy and tool maintenance.

Aluminum:

Aluminum is easier to stamp and form than stainless steel due to its lower strength and ductility. It is less abrasive on tools and allows for relatively complex shapes, though it can be prone to cracking if overworked.

Plastic:

Plastic components are typically molded rather than stamped. Injection molding allows for intricate designs, hollow structures, and integrated features that would be difficult with metals. Plastic’s ease of manufacturing is a significant advantage for complex parts or high-volume production.

Thermal and Electrical Properties

The thermal and electrical characteristics of materials influence their suitability for certain applications.

Stainless Steel:

Stainless steel has low thermal and electrical conductivity compared to aluminum. While this is not an issue for structural applications, it limits its use in components requiring heat dissipation or electrical conduction.

Aluminum:

Aluminum is an excellent conductor of heat and electricity, making it ideal for heat sinks, electronic housings, and electrical components.

Plastic:

Plastics are generally insulating, both electrically and thermally. This property is advantageous for housing electronic components, providing safety, and reducing energy loss in insulating applications.

Aesthetic and Surface Finishing Options

The appearance of components can be important for consumer-facing or visible parts.

Stainless Steel:

Stainless steel offers a sleek, modern look and can be polished, brushed, or coated to achieve various aesthetic effects. Its surface durability maintains appearance over time.

Aluminum:

Aluminum can also be anodized or coated to create decorative finishes and improve corrosion resistance. However, it can scratch more easily than stainless steel.

Plastic:

Plastics offer the greatest variety in color, texture, and transparency. They can be molded into virtually any shape and finished with painting, coating, or texturing to match design requirements.

Environmental Considerations

Sustainability and environmental impact are increasingly important factors in material selection.

Stainless Steel:

Stainless steel is highly recyclable, and recycled content can significantly reduce environmental impact. Its durability also reduces the need for frequent replacement, contributing to sustainability.

Aluminum:

Aluminum is also highly recyclable and can be reprocessed with relatively low energy consumption. Its lightweight nature can reduce energy use in transportation applications.

Plastic:

Plastic recycling is more challenging and less efficient, with many plastics ending up in landfills or incinerated. Biodegradable or recyclable plastics are available but have limitations compared to metals in terms of durability and strength.

Application Suitability

Stainless Steel:

Ideal for applications requiring strength, corrosion resistance, and durability, such as structural components, medical devices, kitchenware, and automotive parts.

Aluminum:

Best for lightweight structures, heat dissipation, and moderate-strength applications, including aerospace, automotive bodies, and electronic housings.

Plastic:

Suitable for low-load applications, insulation, complex shapes, or cost-sensitive products like consumer electronics, packaging, and household goods.

Conclusion

Choosing between stainless steel stamping parts, aluminum components, and plastic parts depends on balancing performance, cost, weight, and environmental factors. Stainless steel excels in strength, durability, and corrosion resistance but is heavy and more costly. Aluminum offers a compromise between strength and lightness, with good corrosion resistance and manufacturability. Plastic is the most versatile in shape, color, and weight but lacks mechanical strength and long-term durability compared to metals.

Ultimately, material selection should consider not only the functional requirements of the application but also manufacturing constraints, cost, and sustainability goals. By carefully analyzing these factors, engineers and designers can make informed decisions that maximize performance while minimizing cost and environmental impact.