When you think about what makes a car great, your mind likely goes to the engine’s horsepower, the sleekness of its design, or the technology inside the cabin. Rarely does anyone marvel at the thousands of precisely shaped pieces of metal that form the vehicle’s very skeleton. This is the world of automotive steel stamping parts, the fundamental, yet often overlooked, components that are essential to every vehicle on the road.

What Are Automotive Stamping Parts?

In simplest terms, automotive stamping is a manufacturing process that uses industrial machinery and dies to transform flat sheet metal into specific, complex shapes. Think of it like a sophisticated cookie cutter for high-strength steel. These custom automotive stamping parts are everywhere in your vehicle. They include visible parts like doors, hoods, and fenders, and a vast array of internal components that you never see, such as brackets, chassis frames, engine cradles, and structural reinforcements within the pillars and roof.

The process is the backbone of auto manufacturing because it allows for the high-volume production of identical parts with exceptional precision and repeatability. Without it, producing millions of vehicles annually with consistent quality and safety standards would be nearly impossible.

The Stamping Process: From Blank to Part

The journey of a stamped metal component is a fascinating blend of brute force and precise engineering. It typically involves several key steps:

-

Blanking: The process begins with large coils of sheet metal, often high-strength steel or aluminum. A blanking press cuts this coil into flat, simpler shapes called “blanks.” These blanks are the raw material for the subsequent forming operations.

-

Forming: The blank is then transferred to a stamping press, which houses a custom-built tool called a die. The die consists of two halves: a punch and a cavity. With immense pressure—often thousands of tons—the press forces the punch into the blank, causing the metal to deform and take the shape of the die. This is not always a single action.

-

Drawing: For parts with significant depth, like an oil pan or a door panel, a specific forming operation called drawing is used. The blank is pulled into the die cavity to create a hollow, cup-like shape without wrinkling or tearing the metal.

-

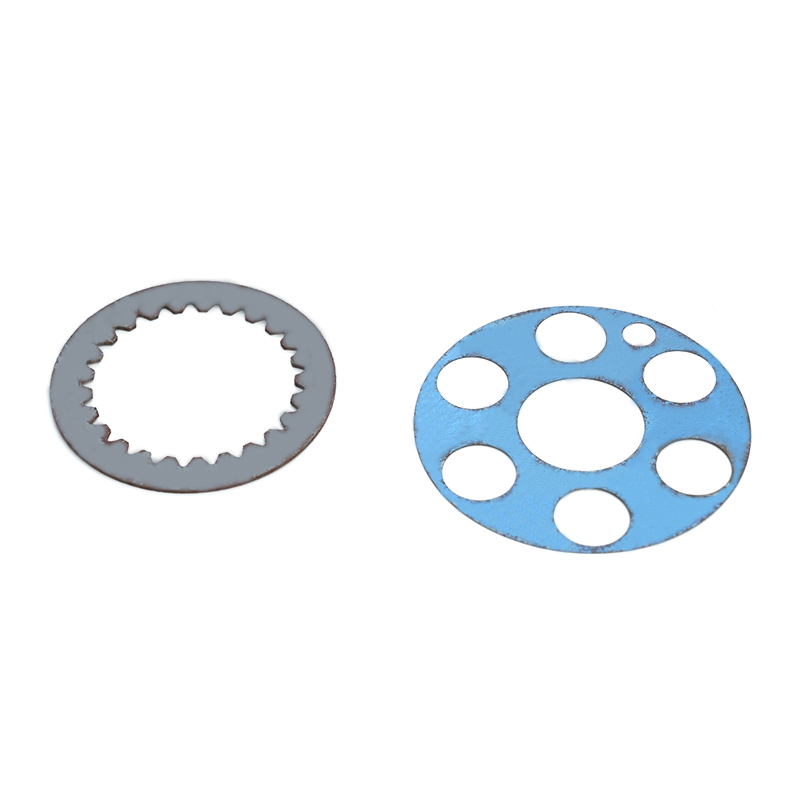

Piercing and Trimming: Simultaneously or in subsequent operations, holes, slots, and cutouts are punched into the part. Excess material, known as flash, is also trimmed away to achieve the final contour.

-

Finishing: The newly formed part may undergo various finishing processes, including deburring (smoothing sharp edges), cleaning, and coating to prevent corrosion before it moves to the assembly line.

Modern stamping facilities often use progressive die stamping, where a single die performs multiple operations—blanking, piercing, drawing, and trimming—in a continuous sequence as the metal strip feeds through the press. This method is incredibly efficient for high-volume precision metal stamping.

Why Steel Stamping is Indispensable to the Auto Industry

The dominance of stamping isn’t accidental. It offers a unique set of advantages that align perfectly with the demands of automotive manufacturing.

-

Strength and Safety: High-strength steel stamping allows manufacturers to create parts that are incredibly strong and rigid yet lightweight. This is crucial for passenger safety cells, crumple zones designed to absorb impact energy, and robust chassis components. The integrity of these stamped parts can be the difference between life and death in a collision.

-

Cost-Effectiveness and Scalability: Once the dies are designed and manufactured—a significant initial investment—the per-part cost for automotive stamping parts is very low. The process is exceptionally fast, with presses capable of producing hundreds of parts per hour. This economies of scale is vital for the auto industry’s profitability.

-

Precision and Consistency: In auto manufacturing, a millimeter’s discrepancy can cause major assembly issues. Stamping dies are engineered to micron-level tolerances, ensuring that every single part produced is identical to the last. This precision metal stamping is non-negotiable for modern automated assembly lines where robots fit parts together.

-

Lightweighting for Efficiency: As the industry pushes for better fuel economy and longer range in electric vehicles, reducing weight is paramount. Advanced stamping techniques allow for the use of thinner, stronger grades of steel and the creation of complex, optimized geometries that provide strength only where it’s needed, eliminating unnecessary weight.

-

Design Flexibility: Stamping can produce an enormous variety of shapes, from simple flat brackets to complex, deeply drawn body panels. This gives automotive designers the freedom to create the curves, lines, and structural elements that define a vehicle’s identity and function.

Quality Control: Ensuring Every Part is Perfect

Given the critical nature of many stamped components, quality control is rigorous. Manufacturers use advanced coordinate measuring machines (CMMs) to scan finished parts and compare them directly to the original digital 3D model. Other techniques include vision systems for surface inspection and destructive testing to verify material properties and weld integrity. This relentless focus on quality ensures reliability and safety from the smallest bracket to the largest body panel.

The Future of Automotive Stamping

The evolution of the automobile is driving innovation in stamping. The shift towards Electric Vehicles (EVs) introduces new challenges and opportunities. Stamping plants are now producing unique components like battery enclosures—large, intricate trays that must be exceptionally strong to protect the battery cells from impact and intrusion.

Furthermore, the use of advanced high-strength steel (AHSS) and ultra-high-strength steel (UHSS) is growing. These materials allow for even greater weight reduction without compromising safety, pushing the boundaries of what stamping dies and presses can handle and requiring continuous advancement in die design and press technology.

In conclusion, while they may be “unsung heroes,” automotive steel stamping parts are the bedrock of the industry. They are a perfect marriage of traditional manufacturing power and cutting-edge innovation, delivering the strength, efficiency, and precision that modern vehicles demand. The next time you see a car, you’ll see more than just a mode of transport; you’ll see thousands of perfectly stamped pieces of metal, working in harmony to get you where you need to go, safely and reliably.