In the relentless pursuit of better, faster, and more efficient products, engineers and designers face a constant battle against a fundamental law of physics: mass. For decades, the equation was simple: more strength required more material, which inevitably meant more weight. Heavier components demand more energy to move, place greater stress on surrounding parts, and limit design possibilities. This paradigm, however, has been decisively broken. The key to this engineering revolution isn’t a mysterious new alloy from science fiction, but a sophisticated understanding of a familiar material—aluminum—and the precision manufacturing process that unlocks its potential: metal stamping.

The goal is no longer just to make something strong. It’s to make it strong where it needs to be, light where it can be, and durable for its entire intended life. This is the promise of high-performance aluminum stamping.

Why Aluminum? More Than Just a Light Metal

While its low density is its most celebrated feature (aluminum is about one-third the weight of steel), focusing solely on weight misses the broader picture. Aluminum’s true value lies in its complete package of properties:

Excellent Strength-to-Weight Ratio: This is the cornerstone of its appeal. Certain aluminum alloys, particularly the 7000-series (alloyed with zinc) and 2000-series (alloyed with copper), can approach the strength of some steels while being significantly lighter. This allows for the design of components that are both robust and lightweight.

Natural Corrosion Resistance: When exposed to air, aluminum instantly forms a thin, hard layer of aluminum oxide on its surface. This layer is highly resistant to corrosion and is self-renewing if damaged. This inherent property makes aluminum stampings ideal for applications exposed to the elements, harsh environments, or chemicals, reducing or eliminating the need for additional protective coatings.

High Electrical and Thermal Conductivity: Aluminum is an excellent conductor of both electricity and heat, second only to copper among common metals. This makes it indispensable for heat sinks, electrical enclosures, busbars, and components where managing thermal or electrical energy is critical.

Excellent Machinability and Formability: While harder alloys exist, most stamping-grade aluminum alloys are highly malleable. This allows them to be pressed, bent, and drawn into complex shapes without cracking or failing, a crucial characteristic for the stamping process.

Non-Sparking and Non-Magnetic: These properties make aluminum a safe choice for applications in volatile environments like oil and gas or chemical plants, as well as in sensitive electronic devices where magnetic interference must be avoided.

Sustainability: Aluminum is 100% recyclable without any loss of its inherent properties. The recycling process requires only about 5% of the energy needed to produce primary aluminum from ore. This makes it a cornerstone of sustainable design and manufacturing.

The Precision Power of Metal Stamping

A material is only as good as the process used to shape it. Metal stamping is a high-volume manufacturing process that uses precision dies and powerful presses to transform flat sheet metal (in this case, aluminum coil or blank) into specific, often complex, shapes.

The process involves a series of operations that can be performed in a single press stroke or across a progression of dies:

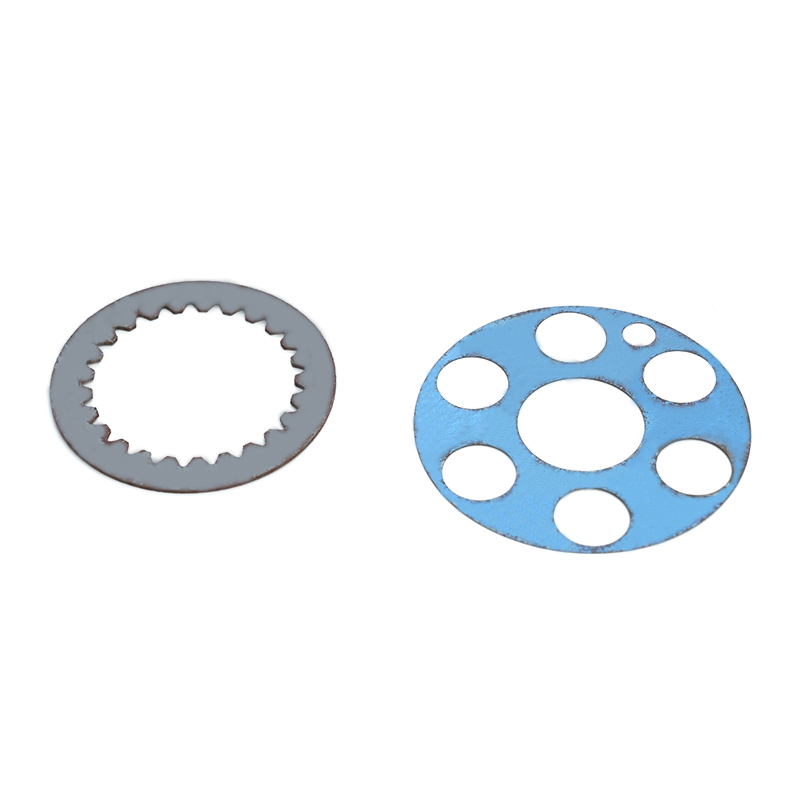

Blanking: Shearing the overall outline of a part from the larger sheet.

Piercing: Punching holes of various sizes and shapes.

Bending: Forming the metal at an angle along a straight axis.

Drawing: Stretching the metal into a deep, cup-like shape, a more complex operation that requires careful control to avoid thinning and tearing.

Coining: Applying high pressure to create precise, sharp details or to smooth surfaces.

For aluminum, the stamping process must be meticulously calibrated. The dies must be designed to account for aluminum’s specific springback characteristics (its tendency to slightly return to its original shape after bending) and its different tensile strength compared to steel. When done correctly, stamping produces parts with exceptional dimensional consistency, high throughput, and minimal material waste.

Engineering for Lasting Strength: It’s in the Design

Creating an aluminum part that is both light and durable isn’t just about choosing the right alloy and stamping it. Lasting strength is engineered into the component through intelligent design and secondary processes.

1. The Critical Role of Alloy Selection:

Not all aluminum is created equal. The choice of alloy is the first and most critical decision. An electrical housing might use a highly conductive 1000-series alloy, while a critical structural aerospace bracket would require a high-strength 7075 alloy. A deep-drawn fuel tank might need the exceptional formability of a 3003 alloy. Understanding the mechanical requirements, the environment, and the forming process is essential to selecting the alloy that will deliver long-term performance.

2. Designing with Geometry: Ribs, Fillets, and Forms:

Strength doesn’t only come from thickness. A flat, thin sheet of aluminum is flexible. But that same sheet, when stamped with strategic ribs, beads, flanges, and curves, becomes incredibly rigid and strong. This concept is known as increasing the moment of inertia. By adding these geometric features, engineers can dramatically increase the stiffness and load-bearing capacity of a part without adding significant mass. A well-placed rib can do the job of a much thicker—and heavier—piece of metal. This is the essence of achieving strength without weight.

3. Avoiding Stress Concentrations:

Sharp internal corners are the Achilles’ heel of any metal part. They act as concentration points for stress, making the part highly susceptible to cracking, especially under cyclic (repeated) loading. The stamping process allows for the incorporation of generous fillets (rounded interior corners) in the die design. These fillets distribute stress over a broader area, significantly enhancing the part’s fatigue life and overall durability.

4. Enhancing Durability with Surface Treatments:

Even with aluminum’s natural corrosion resistance, some applications demand more. The good news is that aluminum is highly receptive to a variety of surface treatments that can further extend its life:

Anodizing: An electrochemical process that thickens the natural oxide layer, creating an extremely hard, durable, and corrosion-resistant surface that can also be dyed in various colors for branding or identification.

Chromate Conversion Coating (Chem Film): Provides a solid protective layer that enhances corrosion resistance and improves adhesion for paint and primers.

Powder Coating: Provides a thick, robust, and attractive polymer coating that offers superior protection against abrasion, chemicals, and UV exposure.

Real-World Applications: Where Lightweight Strength Matters

The benefits of aluminum stampings translate into tangible advantages across countless industries:

Aerospace & Aviation: Every single gram saved on an aircraft translates directly into fuel savings, increased range, and higher payload capacity. From lightweight structural brackets and seat frames to intricate components in avionics systems, aluminum stampings are ubiquitous in the sky because they deliver the required strength and reliability without the mass.

Automotive: The drive for improved fuel efficiency and the rise of electric vehicles (EVs) have made weight reduction a primary design goal. Aluminum stampings are used in body panels, bumper systems, battery enclosures, heat sinks for power electronics, and interior components. For EVs, reducing weight directly extends battery range.

Electronics & Telecommunications: The devices in our pockets and the servers that power the internet require components that manage heat effectively, shield against electromagnetic interference, and are light enough for portable designs. Aluminum stampings are perfect for heat sinks, chassis, frames, and connector shields.

Medical Devices: Portability is often critical for medical equipment. Diagnostic devices, surgical tools, and portable monitors all benefit from the strength, light weight, and ability to be easily sterilized that aluminum stampings provide.

Renewable Energy: Solar panel frames and mounting hardware, as well as components within wind turbines, are exposed to harsh outdoor conditions for decades. Aluminum’s corrosion resistance and strength-to-weight ratio make it an ideal choice for ensuring the long-term structural integrity of renewable energy installations.

Partnering for Success: Beyond the Press

Achieving a high-quality, durable aluminum stamped part is a collaborative effort between the designer and the manufacturer. Here’s what to look for in a stamping partner:

Early Design Involvement (DFM): A good partner will offer Design for Manufacturability (DFM) analysis. They can review your designs early on to suggest modifications that improve stampability, reduce costs, and enhance strength—like optimizing bend radii or suggesting the most efficient grain direction for the material.

Material Expertise: They should have deep knowledge of different aluminum alloys and their properties to guide you toward the best material for your specific application, environment, and budget.

Precision Tool and Die Making: The die is the heart of the stamping process. Precision in die design and construction is non-negotiable for producing parts that are consistent, accurate, and free of defects.

Secondary Process Capabilities: A partner that can also manage finishing processes like anodizing or powder coating simplifies your supply chain and ensures quality control from raw material to finished part.

Conclusion: A Synergy of Material and Process

The quest to build stronger, lighter, and longer-lasting products is not about a single magical solution. It is about the intelligent synergy of material science and precision engineering. Aluminum provides the remarkable raw properties: a blend of lightness, innate strength, and environmental resistance. The metal stamping process provides the method to control and perfect that material, transforming it into complex, high-strength geometries that defy its weight.

By moving beyond the old paradigm of “more weight equals more strength,” and embracing the principles of intelligent design, alloy selection, and precision manufacturing, engineers can truly achieve the best of both worlds. They can create the resilient, reliable, and high-performing components that modern innovation demands, all while shedding unnecessary weight. In a world increasingly focused on efficiency and sustainability, aluminum stamping parts aren’t just a good option—they are the foundation for building a lighter, stronger future.