The automotive chassis serves as the structural backbone of a vehicle, providing strength, stability, and safety. Within this framework, automotive steel stamping parts play a crucial role, enabling manufacturers to create complex structures with precision and consistency.

Understanding Automotive Steel Stamping Parts

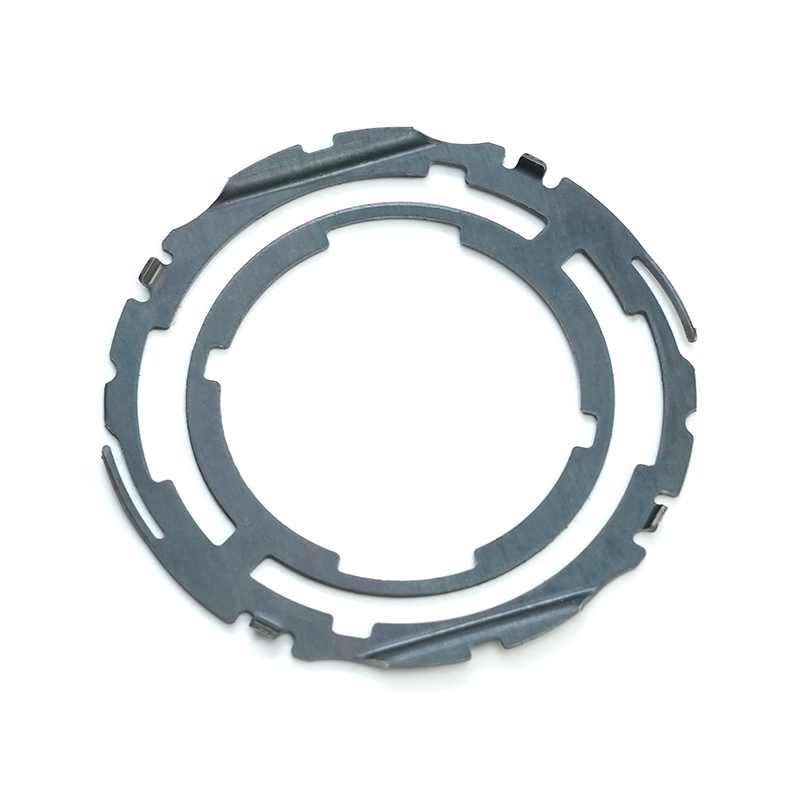

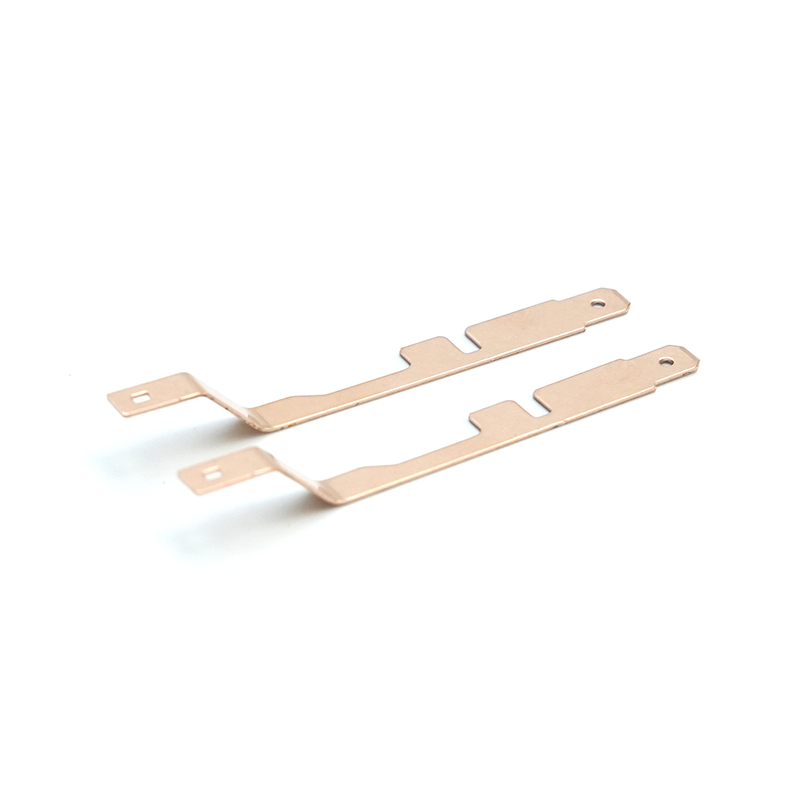

Steel stamping is a manufacturing process in which flat sheets of steel are shaped into specific forms using dies and presses. This method allows for the production of parts with precise dimensions and uniform properties, making it ideal for components that require high strength and reliability. Automotive steel stamping parts include brackets, reinforcements, cross members, and panels that are essential to the chassis structure.

The use of steel in stamping provides several benefits. Steel is strong, durable, and cost effective. It can withstand the stresses of everyday driving while maintaining its shape and integrity over time. By combining steel with advanced stamping techniques, manufacturers can produce parts that are both lightweight and structurally sound.

The Importance of Chassis Design

The chassis is the foundation upon which all other vehicle systems are built. It supports the body, engine, suspension, and drivetrain components while ensuring the vehicle handles safely and efficiently. A well designed chassis must balance rigidity with flexibility. It should be strong enough to protect occupants during collisions while allowing controlled deformation to absorb energy.

In addition to safety, chassis design impacts ride quality and handling. A rigid chassis improves stability and steering response, while a well engineered suspension mounting system allows for smoother rides. The integration of steel stamping parts into chassis design enables engineers to achieve these objectives with precision.

How Steel Stamping Parts Support Chassis Design

Automotive Steel Stamping Parts contribute to chassis design in several ways.

Structural Reinforcement

Many steel stamped components serve as reinforcements within the chassis. Cross members, side rails, and brackets add rigidity to critical areas, distributing loads and minimizing flex. By reinforcing high stress zones, these parts ensure that the chassis can withstand dynamic forces during acceleration, braking, and cornering.

Weight Optimization

Automotive engineers constantly seek to reduce vehicle weight without compromising safety or performance. Steel stamping allows for thin yet strong parts that maintain structural integrity while minimizing material usage. This weight reduction improves fuel efficiency, reduces emissions, and enhances handling.

Crash Safety

In the event of a collision, the chassis must manage impact forces to protect occupants. Steel stamped parts are often designed to deform in a controlled manner, absorbing energy and reducing the risk of injury. Crumple zones, for example, rely on precisely stamped steel components to absorb impact energy while preserving the passenger compartment.

Precision Fit and Assembly

Modern vehicles require exact alignment of chassis components for optimal performance. Steel stamping produces parts with tight tolerances, ensuring that each component fits precisely within the overall structure. This precision reduces assembly errors, improves vehicle quality, and supports consistent performance across production models.

Integration with Other Systems

Steel stamped parts are often used as mounting points for suspension, steering, and drivetrain components. Their precise geometry ensures that these systems operate as intended, maintaining alignment and stability. Additionally, stamped parts can be designed to accommodate wiring harnesses, fuel lines, and other systems without compromising structural integrity.

The Manufacturing Process of Automotive Steel Stamping Parts

Understanding the manufacturing process highlights why steel stamping is well suited for chassis components. The process begins with selecting high quality steel sheets that meet specific strength and ductility requirements. These sheets are then cut, formed, and shaped using specialized dies and presses.

Modern stamping operations often involve multiple stages, including blanking, piercing, bending, and drawing. Advanced simulation software helps engineers predict material behavior and optimize die design, reducing defects and improving production efficiency. Once formed, the stamped parts may undergo additional treatments, such as heat treatment, coating, or surface finishing, to enhance durability and corrosion resistance.

Automation plays a key role in the stamping process. Robotic handling and precision presses ensure consistent quality and reduce production time. This level of control is especially important for chassis components, where accuracy and reliability are critical.

Advantages of Using Steel Stamping Parts in Chassis Design

High Strength-to-Weight Ratio

Steel stamping allows for components that are strong yet lightweight. This combination supports vehicle safety and performance while minimizing fuel consumption.

Cost Effectiveness

Steel is widely available and relatively inexpensive compared to other metals. Stamping processes are highly repeatable, reducing material waste and production costs.

Design Flexibility

Engineers can create complex shapes and features that would be difficult or costly to achieve with alternative methods. Stamped parts can incorporate multiple functions, such as reinforcement and mounting points, in a single component.

Durability and Longevity

Stamped steel parts maintain structural integrity over time, even under harsh driving conditions. They resist deformation, fatigue, and wear, contributing to overall vehicle reliability.

Compatibility with Modern Manufacturing Techniques

Steel stamping integrates well with robotic assembly lines and automated quality control systems. This compatibility supports mass production while maintaining consistent quality.

Challenges and Considerations

Despite its advantages, steel stamping presents certain challenges in chassis design. Engineers must carefully consider material selection, part geometry, and tolerances to prevent issues such as springback, cracking, or uneven thickness. Die design and maintenance are critical, as poorly designed dies can lead to defects and production delays.

Additionally, as vehicles evolve toward lighter materials such as aluminum and high strength steel alloys, manufacturers must balance the benefits of traditional steel stamping with the requirements of new materials. Hybrid approaches that combine stamped steel with other lightweight components are increasingly common in modern chassis design.

Future Trends in Automotive Steel Stamping Parts

The role of steel stamping in chassis design continues to evolve. Advances in high strength steel alloys allow for thinner, stronger parts that further reduce vehicle weight without compromising safety. Incremental improvements in die design, simulation, and automation enhance precision and production efficiency.

Electric vehicles also influence chassis design, as battery placement and weight distribution require careful consideration. Steel stamped parts will continue to play a critical role in supporting these structural and functional requirements.

Conclusion

Automotive steel stamping parts are indispensable in chassis design. They provide structural reinforcement, enable weight optimization, enhance crash safety, and support precise assembly. Through advanced manufacturing processes, these parts allow engineers to create chassis that are strong, reliable, and efficient. As automotive technology continues to evolve, steel stamping will remain a key component in producing vehicles that meet the demands of safety, performance, and sustainability.

By understanding the importance of steel stamped parts, manufacturers and designers can make informed decisions that improve chassis performance and contribute to safer, more efficient vehicles.