Understanding the Role of Hardware Stamping Parts in Modern Manufacturing

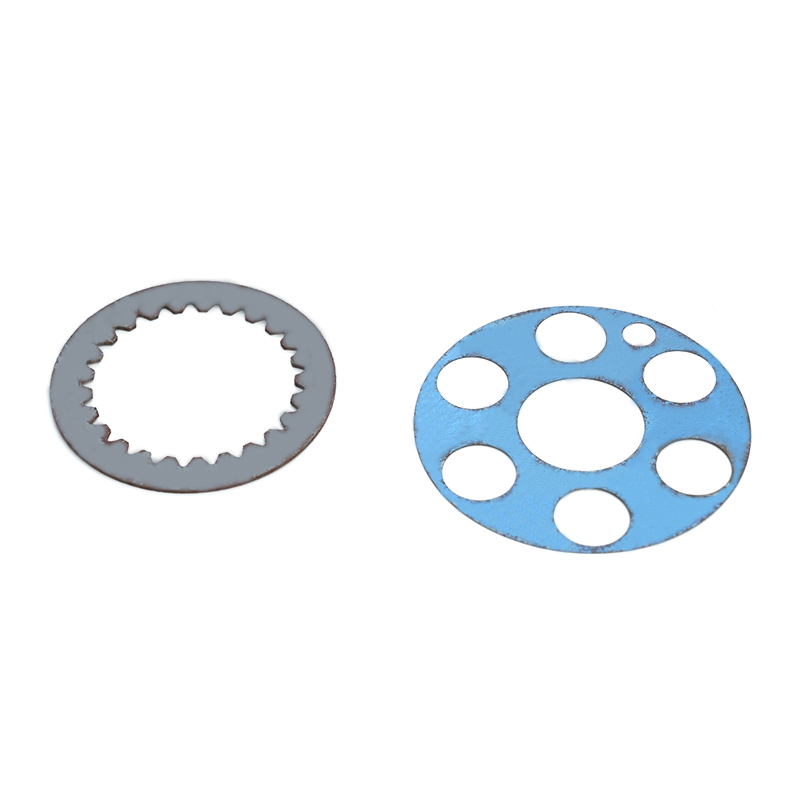

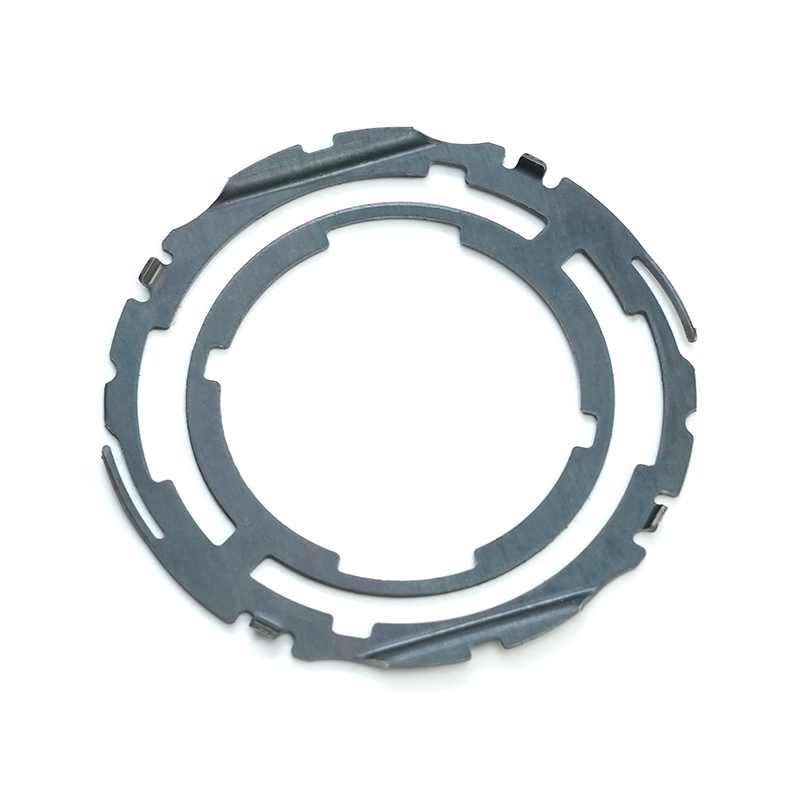

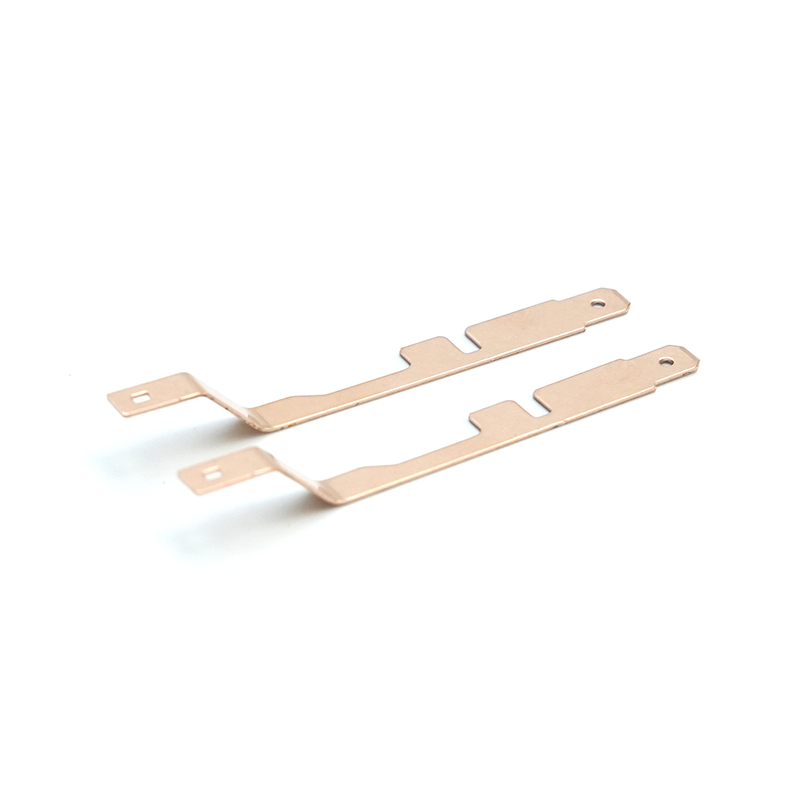

Hardware stamping parts are precision-formed components created through metal stamping processes such as progressive die stamping, deep drawing, and blanking. These parts are widely used in automotive components, electronics housings, industrial machinery, and consumer products due to their cost efficiency, repeatability, and dimensional accuracy.

Combining stamped hardware parts into functional assemblies allows manufacturers to build complex structures while maintaining tight tolerances and production speed. Proper integration improves durability, reduces material waste, and streamlines downstream operations.

Common Materials Used in Stamped Hardware Assemblies

Material selection directly affects part strength, corrosion resistance, and formability. Choosing compatible materials simplifies the assembly process and extends product lifespan.

- Carbon steel for structural strength and affordability

- Stainless steel stamping for corrosion resistance and hygiene-sensitive applications

- Aluminum alloys for lightweight assemblies

- Copper and brass for electrical conductivity

Matching material thickness and mechanical properties ensures consistent forming and secure joining across multiple stamped components.

Design Principles for Combining Stamped Metal Parts

Tolerance Stack-Up Control

Precision stamping relies on tight tolerances, but when multiple parts are assembled together, small dimensional deviations can accumulate. Engineers should use datum referencing and GD&T practices to minimize alignment issues.

Part Geometry for Easy Assembly

Designing features such as self-locating tabs, slots, and pilot holes improves assembly accuracy while reducing reliance on fixtures.

Material Flow and Forming Limit Considerations

Complex stamped hardware parts should avoid sharp corners and excessive draw depth to prevent cracking during forming.

Effective Methods for Joining Hardware Stamping Parts

Selecting the right joining technique depends on load requirements, material type, and production volume.

- Spot welding for steel sheet metal parts in automotive assemblies

- Riveting for mixed-metal combinations

- Clinching for fast, heat-free mechanical bonds

- Threaded fasteners for serviceable assemblies

Automated joining systems significantly improve consistency when combining high-volume stamped components.

Quality Control Measures for Stamped Hardware Assemblies

Maintaining quality throughout the stamping and assembly process prevents costly rework and performance failures.

| Inspection Area | Purpose | Typical Tools |

| Dimensional Accuracy | Verify stamping tolerances | Calipers, CMM |

| Surface Finish | Detect burrs or cracks | Visual inspection |

| Joint Strength | Ensure assembly integrity | Pull testing |

| Material Thickness | Maintain forming consistency | Micrometers |

Inline inspection combined with statistical process control helps identify defects before large production batches are completed.

Cost Optimization Strategies in Stamped Hardware Assemblies

Reducing assembly cost without sacrificing performance is achievable through design and process improvements.

- Use progressive die stamping to reduce part handling

- Standardize fasteners across assemblies

- Integrate multiple features into single stamped parts

- Automate welding and clinching processes

Well-optimized assemblies often reduce overall manufacturing cost by 15–30% compared to manually assembled components.

Typical Applications of Combined Hardware Stamping Parts

Precision metal stamping plays a central role across industries where durability and repeatability matter.

- Automotive seat frames and brackets

- Electrical enclosures and grounding components

- HVAC system supports

- Appliance structural parts

Combining stamped components allows manufacturers to achieve strength comparable to machined parts at a fraction of the cost.

Troubleshooting Common Issues in Stamped Part Assemblies

Misalignment Problems

Often caused by tolerance stack-up or worn tooling, misalignment can be resolved through tighter process controls and fixture upgrades.

Weak Joints

Improper welding parameters or incompatible materials may reduce bond strength. Testing and parameter optimization are essential.

Excessive Burr Formation

Sharp tooling and regular maintenance minimize burrs that interfere with assembly accuracy.

Future Trends in Hardware Stamping and Assembly Integration

Smart manufacturing technologies such as robotic assembly, real-time quality monitoring, and AI-driven process optimization are reshaping metal stamping production lines.

As demand grows for lightweight, high-strength components, combining advanced materials with precision stamping will become even more critical for competitive manufacturing.