Metal stamping is a cold-forming process that uses dies and presses to transform flat sheet metal into specific shapes. This manufacturing technique applies high-tonnage force through mechanical or hydraulic presses to cut, bend, pierce, or form metal without adding heat, making it one of the most efficient methods for mass-producing metal parts across automotive, electronics, aerospace, and appliance industries.

The process works by feeding metal blanks or coils between a punch and die set, where the press applies thousands of pounds of pressure to deform the material into the desired configuration. Modern stamping operations can achieve tolerances as tight as ±0.001 inches and production rates exceeding 1,000 parts per hour, depending on part complexity.

Core Components of Metal Stamping Equipment

Understanding the stamping process requires familiarity with its essential machinery and tooling components that work together to shape metal with precision.

Press Machines

The press machine provides the force necessary for metal deformation. Mechanical presses use flywheel energy and range from 20 to 6,000 tons of force, while hydraulic presses offer more controlled pressure distribution ideal for deep drawing operations. High-speed progressive presses can cycle up to 1,500 strokes per minute for simple parts.

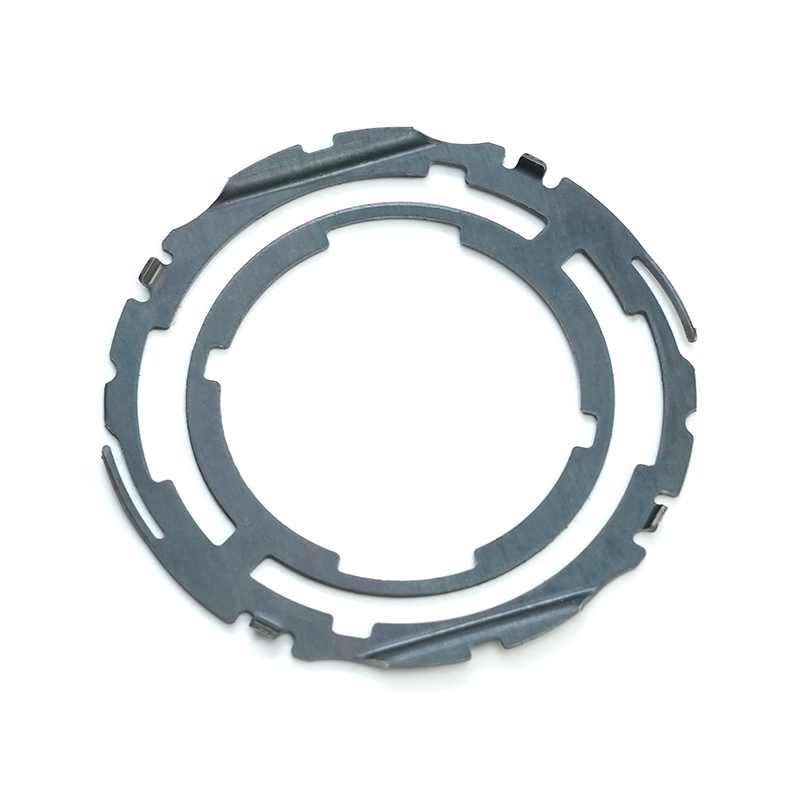

Dies and Tooling

Dies consist of two main parts: the punch (upper tool) and the die (lower tool). The clearance between these components typically ranges from 5% to 20% of material thickness. Tooling costs can range from $2,000 for simple blanking dies to over $500,000 for complex progressive dies with 20+ stations, but this investment is amortized across millions of parts.

Material Feeding Systems

Coil feeding systems automatically advance sheet metal through the press at precise intervals. Servo feeders provide positioning accuracy within ±0.025mm, crucial for maintaining alignment in multi-station progressive dies.

Primary Metal Stamping Operations

Metal stamping encompasses several distinct operations, each designed for specific forming requirements. Manufacturers often combine multiple operations in a single press cycle.

| Operation Type | Description | Typical Applications | Material Waste |

|---|---|---|---|

| Blanking | Cuts part outline from sheet metal | Washers, gaskets, brackets | 10-40% |

| Piercing | Punches holes in metal | Electrical enclosures, panels | 5-15% |

| Bending | Forms angles along straight lines | Brackets, chassis components | 0-5% |

| Drawing | Pulls metal into cavities to form depth | Cans, sinks, automotive panels | 5-20% |

| Coining | Compresses metal to create details | Coins, jewelry, precision parts | 0-3% |

Progressive Die Stamping

This advanced method feeds metal strip through multiple stations in a single die, with each station performing different operations. A typical automotive connector might pass through 15-25 stations, completing blanking, piercing, forming, and bending in one continuous sequence. This approach achieves production rates of 200-1,500 parts per minute for small components.

Transfer Die Stamping

For larger parts, transfer systems mechanically move blanks between separate press stations. This method handles parts up to 2 meters in diameter and is common in automotive body panel production where a single door panel may require 4-6 separate forming operations.

Materials Suitable for Stamping

Material selection directly impacts tool life, part quality, and production costs. The stamping process accommodates various metals, each with specific formability characteristics.

- Low carbon steel: Most common stamping material, offering excellent formability and weldability at 0.5-3.0mm thickness, costs approximately $0.80-$1.20 per kilogram

- Stainless steel: Grades 304 and 316 provide corrosion resistance but require 25-40% more tonnage than carbon steel due to higher tensile strength

- Aluminum alloys: 3003 and 5052 alloys are popular for lightweight applications, reducing part weight by 60% compared to steel while maintaining structural integrity

- Copper and brass: Excellent for electrical components due to conductivity, typically stamped at 0.3-2.0mm thickness with specialized lubrication

- High-strength steel: Advanced high-strength steel (AHSS) with tensile strengths exceeding 1,000 MPa enables lighter automotive structures but accelerates die wear by 30-50%

Material thickness generally ranges from 0.1mm for thin electronic components to 6mm for heavy-duty structural parts. Thicker materials require exponentially greater press tonnage—doubling thickness may require 4-8 times more force depending on material properties.

Step-by-Step Stamping Process Workflow

A typical metal stamping project follows a structured sequence from design to finished parts, with quality checkpoints at each stage.

- Design and Engineering: CAD models are analyzed for stampability, including draw ratios, bend radii, and material flow. DFM (Design for Manufacturing) review identifies potential issues before tooling investment

- Tool Design and Fabrication: Die design takes 2-8 weeks depending on complexity, followed by 4-16 weeks for precision machining and heat treatment of tool steel components

- Material Preparation: Coils are slit to required width (±0.5mm tolerance) and edges deburred to prevent scratching during feeding

- Die Setup and Tryout: Initial runs verify part dimensions, surface quality, and process parameters. Adjustments optimize tonnage, feed length, and timing

- Production Stamping: Automated production runs with in-line sensors monitor part dimensions every 50-500 cycles depending on criticality

- Secondary Operations: Deburring, washing, and heat treatment prepare parts for assembly. Some components require additional operations like tapping, welding, or coating

- Quality Inspection: CMM (Coordinate Measuring Machine) verification, visual inspection, and functional testing ensure parts meet specifications with Cpk values typically above 1.67

Advantages and Limitations of Metal Stamping

Metal stamping offers distinct benefits for high-volume manufacturing but also presents specific constraints that influence process selection.

Key Advantages

- High production speed: Simple parts achieve cycle times under 1 second, enabling annual volumes exceeding 50 million pieces from a single press line

- Low per-part cost: Once tooling is amortized over 100,000+ units, part costs can drop to $0.05-$2.00 depending on size and complexity

- Excellent repeatability: Automated stamping maintains dimensional consistency within ±0.05mm across millions of parts

- Material efficiency: Nesting optimization software arranges parts to achieve 70-90% material utilization, with scrap recycled back to mills

- Enhanced mechanical properties: Cold working during stamping increases material strength by 20-30% through work hardening

Primary Limitations

- High initial tooling investment: Complex progressive dies can cost $100,000-$500,000, requiring production volumes of 50,000+ units for economic viability

- Design constraints: Minimum bend radii must be 1-2 times material thickness to prevent cracking; wall thickness typically remains constant throughout the part

- Limited geometric complexity: Deep draws are restricted to depth-to-diameter ratios of 0.75:1 for single operations; complex 3D shapes may require multiple press stages

- Material springback: Elastic recovery after forming requires overbending by 2-15 degrees depending on material properties, adding complexity to die design

Industry Applications and Real-World Examples

Metal stamping's versatility makes it indispensable across diverse manufacturing sectors, with specific processes optimized for each industry's requirements.

Automotive Manufacturing

Over 500 stamped components comprise a typical vehicle, from structural body panels to small brackets. A single automotive door outer panel requires a 400-800 ton press and 4-6 forming stages. The industry consumes approximately 60% of all stamped metal parts globally, with annual automotive stamping market valued at $95 billion in 2024.

Electronics and Appliances

Precision stamping produces connector terminals, heat sinks, and shielding components with tolerances to ±0.025mm. A smartphone may contain 30-50 stamped metal parts including SIM trays, camera bezels, and internal shielding. High-speed progressive dies run at 600-1,200 strokes per minute for small electronic components.

Aerospace Industry

Aircraft structural components utilize stamping for brackets, clips, and panel reinforcements from aluminum and titanium alloys. Aerospace stamping demands rigorous documentation, with full traceability required for every part including material certifications and process parameters. First article inspection may involve 100+ dimensional checks.

Medical Devices

Surgical instruments, implant components, and device housings are stamped from stainless steel and titanium. Medical stamping operates in ISO 13485 certified facilities with validated processes and 100% inspection for critical dimensions. Parts per million (PPM) defect rates typically remain below 100.

Cost Factors and Economic Considerations

Understanding stamping economics helps manufacturers determine when this process offers the best value compared to alternatives like laser cutting, machining, or casting.

Tooling Investment Breakdown

Tool costs vary dramatically based on complexity and production requirements:

- Simple blanking die (single cavity): $2,000-$8,000

- Compound die (multiple operations, single station): $15,000-$50,000

- Progressive die (8-12 stations): $80,000-$200,000

- Complex progressive die (20+ stations): $250,000-$500,000

Break-Even Analysis

For a moderately complex part, stamping typically becomes cost-effective at production volumes above 10,000-50,000 units. A $100,000 tool producing 5 million parts over its lifetime adds only $0.02 per part, while material and press time might contribute $0.50-$2.00 per part. Competing processes like laser cutting offer lower setup costs but higher per-part costs of $3-$8 for similar components.

Tool Life and Maintenance

Properly maintained stamping dies typically produce 500,000 to 5 million parts before requiring sharpening or refurbishment. Dies for abrasive materials like stainless steel may need sharpening every 100,000-300,000 hits. Preventive maintenance costs run approximately 5-10% of original tool cost annually.

Quality Control and Inspection Methods

Maintaining consistent quality in high-volume stamping operations requires comprehensive monitoring systems and statistical process control.

In-Process Monitoring

Modern stamping lines incorporate sensors that detect:

- Tonnage monitoring: Press force deviations beyond ±5% trigger automatic shutdown, preventing defective parts and die damage

- Part detection: Vision systems verify part presence and orientation, eliminating double-blanks and mis-feeds

- Dimensional measurement: Laser micrometers check critical features every 50-500 cycles with ±0.01mm accuracy

Statistical Process Control

SPC techniques track process capability over time. Target Cpk values of 1.67 or higher ensure defect rates below 1 PPM for critical characteristics. Control charts identify trends before parts exceed specification limits, enabling proactive die adjustments.

Final Inspection Procedures

Depending on criticality, parts undergo sampling plans ranging from AQL 1.0 (640 PPM acceptable) for non-critical features to 100% automated inspection for safety-critical components. CMM verification provides dimensional reports with 30-100+ measured points for first article and periodic validation.

Future Trends in Metal Stamping Technology

Emerging technologies are transforming traditional stamping operations, improving efficiency, precision, and flexibility.

Servo Press Technology

Servo-driven presses replace traditional flywheel mechanics with programmable motion profiles. This enables slide speed adjustments during the stroke, reducing forming time by 20-40% while improving material flow control. Servo presses also consume 30-50% less energy than mechanical equivalents.

Hot Stamping and Warm Forming

Heating materials to 500-950°C before stamping allows forming of ultra-high-strength steels (1,500+ MPa) with minimal springback. This process creates automotive structural components that are 30% lighter while maintaining crash performance. Hot stamping requires specialized dies with integrated cooling channels to quench parts during forming.

Digital Twin and Simulation

Advanced FEA (Finite Element Analysis) software simulates material flow, predicting wrinkles, tears, and springback before physical tooling is built. Digital twin technology reduces die tryout iterations by 40-60%, accelerating time-to-market and reducing development costs by $50,000-$200,000 per project.

Artificial Intelligence Integration

AI algorithms analyze real-time sensor data to predict tool wear, optimize press parameters, and detect quality deviations. Machine learning models trained on historical production data can reduce scrap rates by 15-25% through early anomaly detection and automated process adjustments.