Aluminum alloy stamping parts have become increasingly prevalent in the automotive industry over the past few decades. Their unique combination of lightweight properties, strength, and corrosion resistance makes them an ideal choice for a wide range of automotive applications.

Understanding Aluminum Alloy Stamping Parts

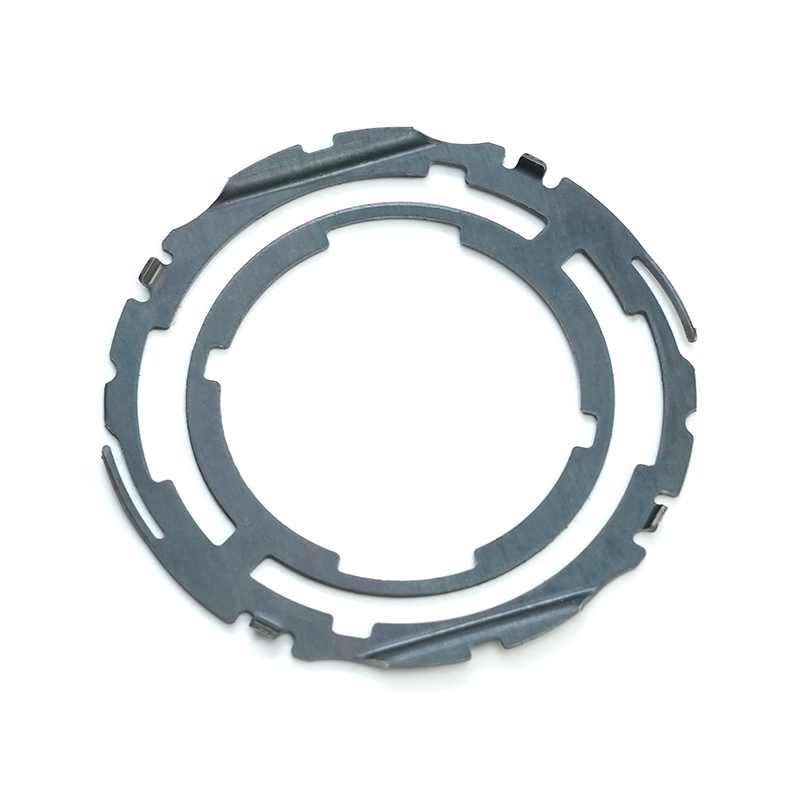

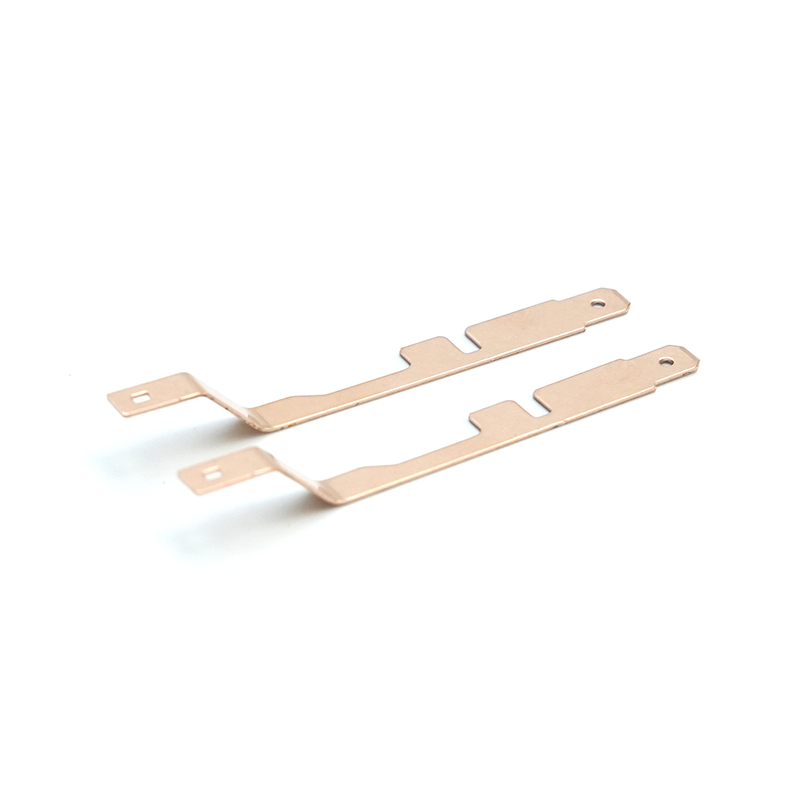

Aluminum alloy stamping parts are components produced by shaping aluminum alloys under high pressure, typically using a stamping press. The process involves pressing a flat aluminum sheet or coil into a desired shape with the help of dies. This technique allows for the production of complex geometries and high-precision components suitable for mass production. Aluminum alloys, in particular, offer a favorable strength-to-weight ratio, making them an attractive material for automotive applications where weight reduction is a priority.

Advantages of Aluminum Alloy Stamping Parts in Automotive Use

Before examining specific applications, it is important to understand why aluminum alloy stamping parts are widely adopted in the automotive sector:

- Lightweight: Aluminum is significantly lighter than traditional steel, which helps improve fuel efficiency and reduce emissions in vehicles. Lighter components also enhance handling and performance.

- Corrosion Resistance: Aluminum alloys resist rust and corrosion, making parts more durable and suitable for both interior and exterior automotive applications.

- Design Flexibility: Stamping allows for the creation of complex and precise geometries, which can accommodate both structural and aesthetic requirements.

- Cost-Effective for Mass Production: Once dies are manufactured, aluminum stamping can be highly efficient, producing consistent parts at scale.

- Sustainability: Aluminum is highly recyclable, supporting environmental goals and reducing the automotive industry’s carbon footprint.

These advantages collectively make aluminum alloy stamping parts a compelling choice for modern vehicle manufacturing.

Typical Applications in Automotive Industries

1. Body Panels

One of the most visible applications of aluminum alloy stamping parts is in vehicle body panels. Doors, hoods, trunk lids, fenders, and roof panels are commonly produced using aluminum stamping. The use of aluminum reduces the overall vehicle weight without compromising strength, contributing to better fuel economy and handling. Moreover, aluminum body panels are resistant to corrosion, which extends the lifespan of the vehicle.

2. Chassis Components

Aluminum stamping is also used to manufacture chassis components, including subframes, cross members, and reinforcements. These components must maintain structural integrity while minimizing weight. Aluminum alloy stamping allows for precise shaping, ensuring parts can absorb and distribute loads effectively while contributing to overall vehicle safety.

3. Engine Components

Certain engine components benefit from aluminum alloy stamping due to their need for both strength and thermal conductivity. While casting is more common for engine blocks, stamped aluminum is often used for parts like brackets, housings, and covers. These parts help reduce engine weight and improve heat dissipation, which enhances overall engine efficiency.

4. Suspension Parts

Suspension systems, including control arms, brackets, and linkages, sometimes employ aluminum alloy stamping parts. The lightweight nature of aluminum reduces unsprung weight, improving vehicle handling and ride comfort. Additionally, the precision offered by stamping ensures that these components meet stringent dimensional and performance requirements.

5. Heat Shields and Underbody Components

Modern vehicles generate significant heat from the engine and exhaust system. Aluminum alloy stamping parts are widely used to produce heat shields, protecting sensitive components and improving passenger safety. Similarly, underbody panels, which shield the vehicle from road debris, benefit from aluminum’s strength and corrosion resistance.

6. Interior Components

Aluminum stamping is not limited to structural applications. Certain interior parts, such as decorative trims, seat frames, and reinforcement brackets, are made from stamped aluminum. These applications take advantage of aluminum’s aesthetic appeal, lightweight properties, and durability.

7. Electrical and Electronic Component Housings

As vehicles incorporate more electronics and hybrid or electric systems, aluminum alloy stamping parts are increasingly used for housings and enclosures. These components provide structural support, thermal management, and electromagnetic shielding, which is essential for sensitive electronic systems.

Considerations for Using Aluminum Alloy Stamping Parts in Vehicles

While aluminum stamping offers numerous benefits, there are considerations to keep in mind:

- Tooling Costs: Initial die creation can be expensive, making aluminum stamping more suitable for medium-to-high-volume production.

- Joining Techniques: Unlike steel, aluminum requires specialized joining methods, such as riveting, adhesive bonding, or welding with compatible techniques.

- Springback Effect: Aluminum tends to spring back slightly after stamping, requiring precise die design to maintain dimensional accuracy.

- Material Selection: Different aluminum alloys offer varying levels of strength, corrosion resistance, and formability. Choosing the correct alloy is crucial for component performance.

Emerging Trends in Automotive Aluminum Stamping

With increasing demand for electric vehicles (EVs) and lightweight, fuel-efficient designs, aluminum alloy stamping is likely to expand its presence in automotive manufacturing. Some emerging trends include:

- Multi-Layer Stamping: Combining aluminum with other materials, such as steel or composites, to optimize strength and weight.

- Advanced High-Strength Alloys: Developing aluminum alloys that provide improved formability without sacrificing strength.

- Integration with Additive Manufacturing: Using stamping in combination with 3D-printed components to produce complex assemblies efficiently.

Conclusion

Aluminum alloy stamping parts have become a cornerstone of modern automotive engineering. From body panels to chassis components, suspension parts, heat shields, and interior structures, stamped aluminum plays a critical role in reducing vehicle weight, improving fuel efficiency, and maintaining structural integrity. While there are considerations regarding tooling, joining, and material selection, the advantages of aluminum stamping—lightweight, corrosion-resistant, and versatile—make it a reliable and increasingly popular choice in the automotive industry.

As vehicles continue to evolve, especially with the rise of electric mobility and lightweight design priorities, aluminum alloy stamping parts will likely become even more integral to the production of safer, more efficient, and environmentally responsible automobiles.