Copper stamping parts are widely used in industries ranging from automotive to electronics due to their excellent electrical conductivity, thermal conductivity, and corrosion resistance. However, like all metal components, their performance can vary significantly under extreme conditions, especially high temperatures. Understanding how copper stamping parts behave under heat is critical for engineers, designers, and manufacturers who aim to maintain safety, efficiency, and longevity in their products.

Overview of Copper Stamping Parts

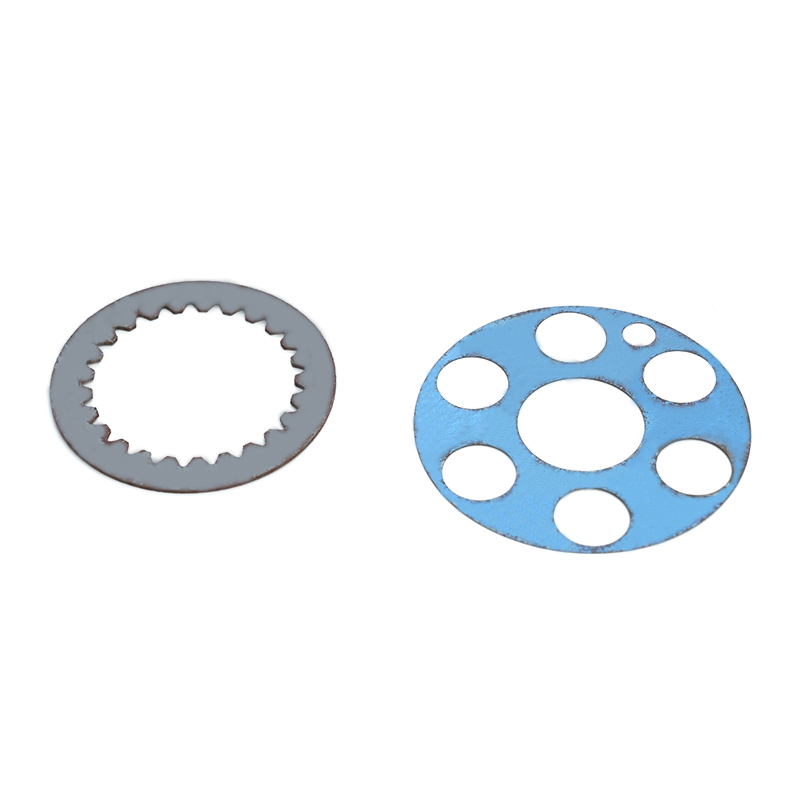

Copper stamping parts are components created by pressing copper sheets into specific shapes using stamping machinery. This process can produce highly precise parts in large volumes, making it ideal for connectors, terminals, heat sinks, and various electrical or mechanical components.

Key advantages of copper stamping parts include:

- Excellent electrical conductivity – crucial for electrical and electronic applications.

- High thermal conductivity – allowing efficient heat dissipation.

- Corrosion resistance – reduces oxidation and increases durability.

- Formability – copper can be shaped with high precision.

Despite these benefits, copper is a relatively soft metal compared to alloys like steel. Its mechanical properties can change significantly when exposed to high temperatures, which is why understanding its thermal behavior is essential.

Thermal Properties of Copper

To understand the performance of copper stamping parts under heat, we need to consider the inherent thermal properties of copper:

- Melting Point: Copper melts at around 1,085°C (1,985°F). While this is relatively high, it is lower than many high-strength alloys, meaning that extreme heat can quickly compromise structural integrity.

- Thermal Conductivity: Copper has one of the highest thermal conductivities among metals (approximately 400 W/m·K). This means copper parts can dissipate heat efficiently, reducing localized thermal stress in most applications.

- Coefficient of Thermal Expansion (CTE): Copper expands approximately 16.5 × 10^-6 /°C when heated. In assemblies where copper parts are combined with materials of different CTEs (like aluminum or steel), this expansion can create mechanical stresses or misalignment.

The combination of high conductivity and moderate expansion makes copper suitable for thermal management applications, but its relatively low strength at elevated temperatures can be a limitation.

How High Temperatures Affect Copper Stamping Parts

When exposed to high temperatures, copper stamping parts can undergo several changes:

Mechanical Strength Reduction

Copper’s tensile strength and hardness decrease with increasing temperature. While room-temperature tensile strength for pure copper is about 210 MPa, it can drop significantly as the temperature rises. In applications where the copper part bears mechanical loads, this weakening can result in deformation or failure.

Creep Behavior

Creep refers to the slow, permanent deformation of a material under constant stress at elevated temperatures. Copper is particularly susceptible to creep when exposed to temperatures above 0.4 times its melting temperature (around 400–450°C). In long-term high-temperature applications, such as engine components or industrial machinery, creep can compromise dimensional stability.

Oxidation and Surface Degradation

Although copper forms a protective oxide layer that resists further corrosion, prolonged exposure to high temperatures can lead to accelerated surface oxidation. This may result in reduced conductivity, discoloration, and surface roughness, which could be critical for electrical contacts or aesthetic components.

Thermal Expansion and Warping

Copper expands when heated, and in assemblies with tight tolerances, this can cause warping, misalignment, or interference with other parts. Engineers must account for thermal expansion when designing assemblies that operate at high temperatures.

Factors Influencing High-Temperature Performance

The behavior of copper stamping parts under heat depends on several key factors:

Alloying Elements

Pure copper is soft and ductile, but alloying with elements such as nickel, tin, or beryllium can enhance strength and thermal stability. For example, beryllium copper retains much of its strength even at temperatures exceeding 200°C, making it suitable for high-temperature spring contacts and connectors.

Part Geometry

Thin, intricate stamping parts heat up more quickly and are more prone to deformation than thicker parts. Sharp corners and thin sections are particularly vulnerable to warping under thermal stress.

Heat Exposure Duration

Short bursts of high heat (e.g., during soldering or welding) may cause temporary expansion but rarely result in long-term failure. Continuous exposure to high temperatures, however, can accelerate creep, oxidation, and mechanical degradation.

Surface Treatments

Coatings, plating, or passivation layers can enhance high-temperature performance. For example, tin or nickel plating can protect copper stamping parts from oxidation, maintaining both mechanical and electrical performance under heat.

Practical Applications and Temperature Limits

Understanding real-world applications helps define the practical temperature limits for copper stamping parts:

Electrical Connectors

In electrical applications, copper stamping parts are often exposed to current-induced heating. Standard copper connectors can safely handle temperatures up to 150–200°C. For higher-temperature environments, beryllium copper or nickel-plated copper is often preferred.

Automotive Components

Copper parts in engines or electrical systems may experience temperatures between 150°C and 250°C. Alloyed copper is frequently used in these applications to ensure dimensional stability and resistance to creep.

Industrial Equipment

High-temperature industrial machinery may expose copper stamping parts to 300°C or higher. In these cases, special heat-resistant alloys, thicker geometries, or additional cooling measures are required.

Electronics and Thermal Management

Copper is extensively used in heat sinks due to its excellent thermal conductivity. While the heat may be high locally, copper’s ability to quickly dissipate heat prevents hot spots, maintaining the integrity of surrounding components.

Strategies to Optimize Performance

Several strategies can help maximize the performance of copper stamping parts under high temperatures:

Material Selection

Choosing the right copper alloy is crucial. Beryllium copper, phosphor bronze, or nickel-plated copper can retain mechanical strength and resist oxidation at elevated temperatures.

Proper Design

- Avoid thin or delicate sections that may warp.

- Add radii instead of sharp corners to reduce stress concentrations.

- Allow for thermal expansion in assemblies by including gaps or flexible joints.

Surface Treatments

Plating with nickel, tin, or other heat-resistant materials can reduce oxidation and maintain conductivity. High-temperature coatings can also reduce thermal stress and wear.

Thermal Management

In high-temperature applications, proper cooling strategies—like heat sinks, ventilation, or thermal interface materials—can prevent copper parts from exceeding safe temperature limits.

Testing and Simulation

Finite element analysis (FEA) and thermal simulations can predict how copper stamping parts behave under heat, helping engineers design components that resist deformation and maintain performance.

Common Challenges

Even with careful design and material selection, copper stamping parts can face challenges under high temperatures:

- Creep deformation: Long-term stress at moderate heat can change part dimensions.

- Oxidation and discoloration: High temperatures accelerate surface changes, which can affect electrical performance.

- Assembly issues: Differential expansion between copper and other materials may cause misalignment or mechanical stress.

- Material fatigue: Repeated thermal cycling can reduce strength and lead to cracks over time.

Addressing these challenges requires an integrated approach that combines material science, engineering design, and thermal management.

Conclusion

Copper stamping parts offer excellent thermal and electrical conductivity, making them invaluable in high-performance applications. However, their performance under high temperatures depends heavily on material composition, geometry, surface treatment, and thermal management strategies. By understanding how copper behaves when heated and implementing design practices to mitigate risks, engineers can ensure reliable performance, long-term durability, and optimal efficiency for components exposed to heat.

While pure copper has limitations at elevated temperatures, alloyed or treated copper stamping parts can withstand demanding thermal conditions. Selecting the right material, optimizing design, and employing protective measures can make copper stamping parts not just functional but highly reliable under heat.

For anyone designing or using copper stamping parts in high-temperature environments, careful planning, testing, and material choice are essential. With these considerations in mind, copper stamping parts can continue to deliver exceptional performance across a wide range of industrial, automotive, and electronic applications.