In the intricate world of modern manufacturing, the demand for components that are lightweight, durable, cost-effective, and precisely formed is relentless. Aluminum stamping parts have risen to meet this challenge, becoming indispensable across a staggering array of industries. From the vehicle you drive to the electronics you rely on, stamped aluminum components play a vital, often unseen, role. Understanding the process, benefits, and key considerations empowers designers, engineers, and procurement specialists to leverage this versatile technology effectively.

Why Aluminum? The Material Advantage

Aluminum’s unique properties make it exceptionally well-suited for stamping:

Lightweight: Aluminum’s low density (approximately one-third that of steel) is a primary driver for its use, especially in automotive and aerospace applications where reducing weight directly translates to improved fuel efficiency and performance. This is crucial for lightweight metal components.

Strength-to-Weight Ratio: Certain aluminum alloys offer impressive strength relative to their weight, providing structural integrity without excessive mass. High strength aluminum alloys are frequently specified for demanding applications.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, offering excellent resistance to corrosion, particularly when anodized. This makes it ideal for corrosion resistant stamped parts exposed to harsh environments or requiring longevity.

Excellent Conductivity: Aluminum is a superb conductor of both heat and electricity. This property is harnessed in aluminum electrical components (busbars, connectors) and aluminum heat sinks for thermal management in electronics and power systems.

Formability: While not as ductile as some steels, many aluminum alloys exhibit good formability, allowing them to be stamped into complex shapes with tight tolerances through processes like deep drawing and bending.

Recyclability: Aluminum is highly recyclable with minimal degradation in quality, making it an environmentally responsible choice. This supports the use of sustainable metal fabrication processes.

Machinability & Surface Finish: Aluminum can be easily machined post-stamping if needed and accepts a wide variety of surface finishes (anodizing, painting, powder coating, plating) for aesthetics or enhanced functionality. Options like anodized aluminum stamping are popular for durability and appearance.

The Stamping Process: Shaping Metal with Force

Stamping is a high-volume, high-speed manufacturing process that transforms flat sheet metal (blanks) into specific shapes using a press and specialized tooling (dies). For aluminum, the process involves several key stages:

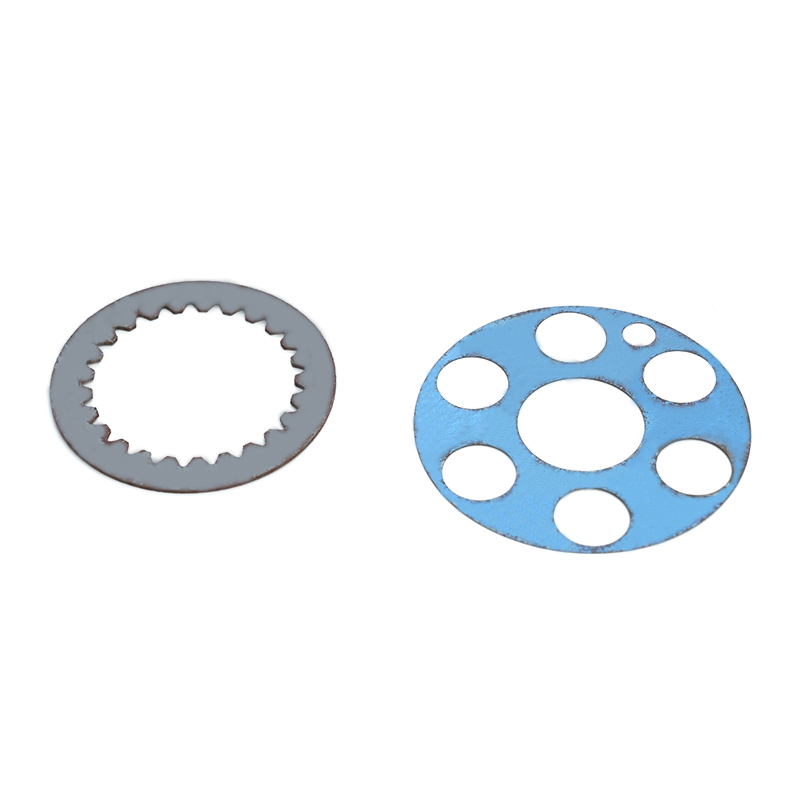

Blanking/Piercing: The initial step often involves cutting the outline of the part (blanking) and punching any required internal holes or features (piercing) from a larger sheet or coil.

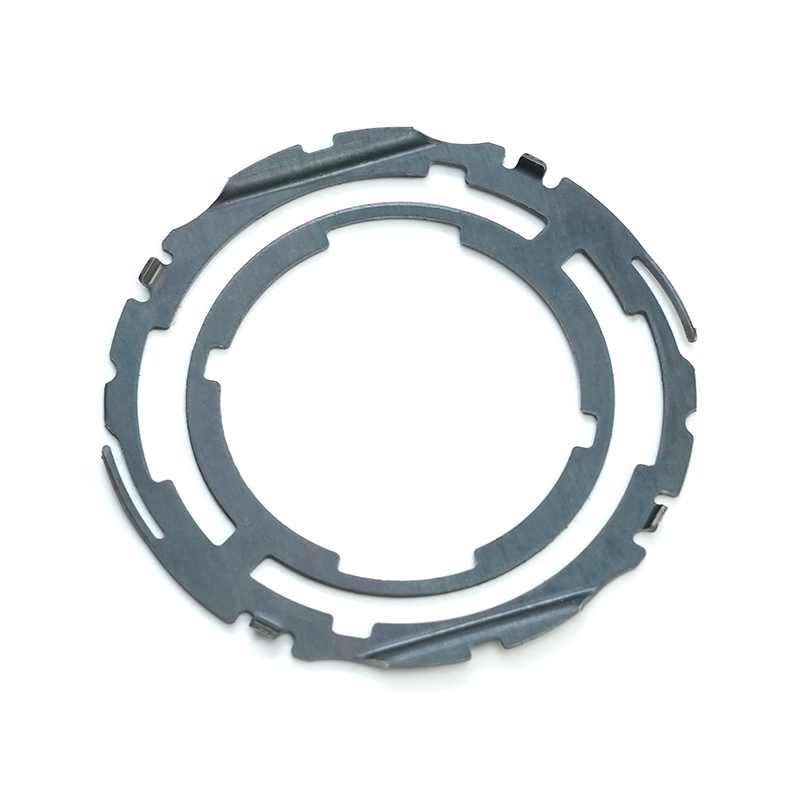

Forming: This is the core of stamping. The aluminum blank is plastically deformed into the desired 3D shape. Common forming operations include:

Bending: Creating angles or flanges.

Deep Drawing: Pulling the metal into a die cavity to form deep, cup-like shapes (common for enclosures, housings).

Flanging: Creating a raised rim or edge.

Embossing: Creating raised or recessed features on the surface.

Coining: Applying extremely high pressure to achieve precise dimensions, sharp details, or specific surface textures.

Trimming: Removing excess material (flash) left from forming operations.

Secondary Operations: Depending on the part, additional steps like tapping threads, riveting, welding, or applying finishes (aluminum surface finishing) may be performed.

Stamping can be done as a single-stage operation for simple parts or, more commonly, using progressive die stamping. In progressive dies, the sheet metal coil feeds through multiple stations within a single die set. Each station performs a different operation (pierce, bend, form, trim) in sequence until the finished part is ejected at the final station. This is highly efficient for complex, high volume metal stamping.

Key Advantages of Aluminum Stamping

High Production Rates & Cost Efficiency: Once the tooling is built, stamping produces parts rapidly and consistently, significantly reducing per-part costs, especially for large volumes. This makes custom aluminum stamping economical at scale.

Precision and Consistency: Modern presses and precision dies allow for extremely tight tolerances and highly repeatable part geometry, essential for precision aluminum stamping and complex assemblies.

Complex Geometries: Stamping can create intricate shapes and features (bends, flanges, ribs, louvers, complex curves) that would be difficult or expensive to achieve with other methods like machining.

Material Efficiency: Nesting parts efficiently on the sheet and minimizing scrap through optimized tooling design contributes to material savings.

Excellent Surface Quality: Stamped parts typically have smooth surfaces from the start, requiring less finishing work compared to cast or forged parts. The surface is ideal for subsequent treatments like anodized aluminum stamping.

Scalability: Stamping is suitable for both prototype runs (using softer tooling materials or different techniques) and massive production volumes.

Design Considerations for Success

Designing parts specifically for the aluminum stamping process is critical for manufacturability, cost, and quality:

Material Selection: Choose the appropriate aluminum alloy (e.g., 1100, 3003, 5052, 6061) based on required strength, formability, corrosion resistance, conductivity, and weldability. Consult with your stamper early.

Radii: Incorporate generous bend radii. Sharp corners increase stress concentration and risk cracking. Minimum bend radius depends on alloy, temper, and thickness.

Hole and Slot Placement: Maintain adequate distances from edges and between holes to prevent distortion or tearing during forming. Hole diameters should generally be at least equal to the material thickness.

Tolerances: Specify realistic tolerances achievable with stamping. While precision is possible, demanding unnecessarily tight tolerances on all features drastically increases tooling cost and complexity. Focus critical tolerances where absolutely needed.

Symmetry: Symmetrical parts are often easier and cheaper to produce and can sometimes nest better on the sheet.

Avoid Excessive Depth in Drawing: Deep drawing aluminum requires careful design and potentially multiple draws to avoid wrinkling or tearing. Consult with your stamper on depth-to-diameter ratios.

Consider Grain Direction: Aluminum sheet has a grain direction from rolling. Forming across the grain can lead to cracking in some alloys/tempers; bending is best done parallel to the grain unless the design necessitates otherwise.

Draft Angles (for formed features): Small draft angles on walls can significantly aid part ejection from the die, especially in deep drawn parts.

Applications: Where Aluminum Stamping Shines

The versatility of aluminum stamping parts ensures their presence in nearly every sector:

Automotive: Bracket assemblies, heat shields, electrical connectors, sensor housings, interior trim components, EV battery enclosures (lightweight metal components, corrosion resistant stamped parts).

Aerospace: Non-structural brackets, enclosures, covers, trays, heat sinks (high strength aluminum alloys, precision requirements).

Electronics: Shielding cans, chassis, heat sinks, connectors, battery contacts (aluminum electrical components, aluminum heat sinks, anodized aluminum stamping).

Consumer Goods: Appliance panels and housings, cookware, lighting fixtures, hardware, decorative trim.

Industrial Machinery: Guards, covers, panels, motor components, fluid handling parts (custom aluminum stamping).

Renewable Energy: Solar panel frames, mounting hardware, inverter components (sustainable metal fabrication).

Medical Devices: Equipment housings, trays, instrument components (requiring high precision and cleanability).

Ensuring Quality: Beyond the Press

Producing high-quality aluminum stamping parts requires more than just a press:

Robust Tooling: High-quality, precisely machined dies are fundamental. Tooling design and maintenance are critical investments.

Material Control: Consistent material properties (alloy, temper, thickness) from reputable suppliers are essential.

Process Control: Monitoring press tonnage, speed, lubrication, and alignment ensures consistent results. Precision aluminum stamping relies heavily on this.

Inspection: Rigorous inspection at various stages (incoming material, first article, in-process, final) using techniques like CMM (Coordinate Measuring Machine), optical comparators, go/no-go gauges, and visual checks is non-negotiable. This verifies adherence to specifications for complex metal enclosures or simple brackets alike.

Finishing Expertise: Proper surface preparation and application of finishes like anodizing or painting require specialized knowledge and controlled processes.

Conclusion

Aluminum stamping parts represent a remarkable synergy of material science and manufacturing precision. By harnessing aluminum’s inherent advantages – lightness, strength, corrosion resistance, and conductivity – through the high-speed, cost-effective stamping process, manufacturers can produce complex, reliable components that drive innovation across countless industries. Success hinges on thoughtful design for manufacturability, collaboration with experienced stamping partners, stringent quality control, and a deep understanding of both the material’s behavior and the process’s capabilities. Whether you’re designing the next generation of electric vehicles, advanced medical devices, or robust industrial equipment, aluminum stamping offers a proven, versatile, and efficient pathway to turning innovative ideas into tangible, high-performing reality. Understanding its potential and intricacies empowers smarter design choices and more effective manufacturing outcomes.