What Makes Stamped Iron the Preferred Choice for Solenoid Valve Housings

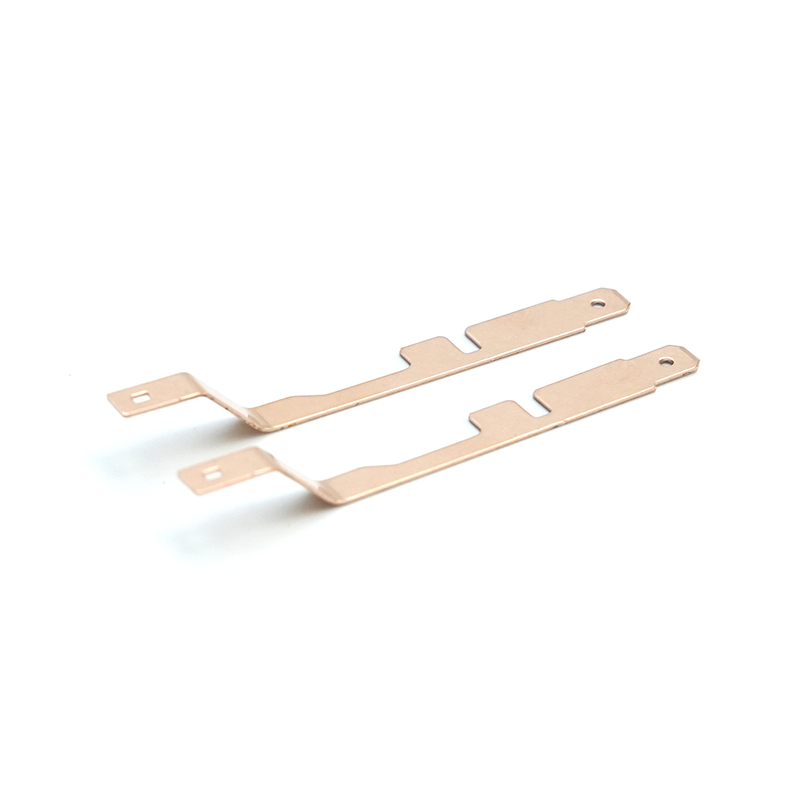

Stamped iron solenoid valve housings represent a cost-effective and reliable solution for fluid control applications across numerous industries. The stamping process enables manufacturers to produce housings with dimensional accuracy within ±0.1mm tolerance while maintaining material thickness consistency of 1.5-3.0mm. This manufacturing method reduces production costs by 30-40% compared to cast iron alternatives while delivering comparable mechanical strength and magnetic permeability essential for electromagnetic actuation.

The ferromagnetic properties of stamped iron create an efficient magnetic circuit, allowing the solenoid coil to generate sufficient force with lower power consumption. Industry data shows that properly designed stamped iron housings achieve magnetic flux density of 1.2-1.5 Tesla, ensuring reliable valve operation across pressure ranges from vacuum to 250 bar depending on valve design and seal configuration.

Manufacturing Process and Quality Control Standards

The production of stamped iron solenoid valve housings involves precision metal forming techniques that transform flat steel sheets into three-dimensional functional components. The process begins with material selection, typically using low-carbon steel grades such as AISI 1008 or 1010 with carbon content below 0.15%, which provides optimal formability and magnetic properties.

Progressive Die Stamping Operations

Progressive die stamping completes multiple operations in a single press stroke, including blanking, piercing, forming, and bending. Modern hydraulic presses operating at 150-400 tons of force can produce 30-60 housings per minute with consistent quality. The dies themselves are precision-machined from hardened tool steel with surface finishes of Ra 0.4μm or better to ensure smooth part ejection and extended tool life exceeding 500,000 cycles.

Critical Quality Checkpoints

- Dimensional verification using CMM equipment to confirm hole positions within ±0.05mm

- Surface flatness inspection ensuring parallelism better than 0.02mm across mating surfaces

- Magnetic permeability testing to verify minimum relative permeability of 2000

- Burr inspection and deburring operations to achieve edge radii of 0.1-0.2mm

- Coating thickness measurement for corrosion protection layers

Material Properties and Performance Characteristics

The selection of stamped iron for solenoid valve housings is driven by specific material properties that directly impact electromagnetic performance and structural integrity. Understanding these characteristics enables engineers to optimize valve designs for specific operating conditions.

| Property | Value Range | Impact on Performance |

|---|---|---|

| Tensile Strength | 300-420 MPa | Withstands internal pressure and mechanical stress |

| Yield Strength | 180-250 MPa | Prevents permanent deformation under load |

| Relative Permeability | 2000-5000 μr | Enables efficient magnetic flux concentration |

| Coercivity | 50-80 A/m | Minimizes residual magnetism after deactivation |

| Thermal Conductivity | 50-60 W/(m·K) | Dissipates heat from coil operation |

The low coercivity of stamped iron is particularly important for AC solenoids operating at 50-60 Hz, as it minimizes hysteresis losses and reduces heat generation. Field testing demonstrates that stamped iron housings maintain operational temperatures 15-20°C lower than comparable stainless steel housings under continuous duty cycles.

Surface Treatment and Corrosion Protection Methods

Raw stamped iron is susceptible to oxidation and corrosion, requiring protective coatings to extend service life in demanding environments. The selection of appropriate surface treatments depends on the operating medium, temperature range, and required service intervals.

Electroplating Options

Zinc plating with chromate conversion coating provides 240-720 hours of salt spray resistance according to ASTM B117 testing standards. This economical treatment is suitable for indoor applications and non-corrosive fluid systems. For enhanced protection, nickel-phosphorus electroless plating achieves 1000+ hours of salt spray resistance with coating thickness of 10-15 micrometers, making it appropriate for hydraulic systems and moderately corrosive environments.

Powder Coating and E-coating

Epoxy powder coatings applied at 150-200 micrometers thickness provide excellent chemical resistance and electrical insulation properties. Electrophoretic coating (E-coating) penetrates recessed areas and complex geometries more effectively than powder coating, achieving uniform coverage with 20-30 micrometers thickness and 1500+ hours salt spray resistance. E-coating is particularly beneficial for multi-cavity housings with internal passages where manual coating application is impractical.

Design Considerations for Optimal Electromagnetic Performance

Effective solenoid valve housing design requires careful attention to magnetic circuit geometry and air gap management. The housing must provide a low-reluctance path for magnetic flux while accommodating mechanical components and sealing elements.

Critical Design Parameters

- Wall thickness optimization: Maintaining 2.0-2.5mm minimum thickness prevents magnetic saturation while preserving structural strength

- Air gap control: Limiting working air gaps to 0.3-0.8mm maximizes magnetic force; every 0.1mm increase reduces force by approximately 15%

- Corner radius design: Generous internal radii (minimum 1.0mm) reduce stress concentration and improve magnetic flux distribution

- Mounting hole placement: Positioning fastener holes away from high-flux regions prevents localized saturation and maintains force consistency

Finite element analysis (FEA) of magnetic circuits reveals that optimized housing geometries increase actuator force by 25-35% compared to basic cylindrical designs, enabling valve operation at lower power consumption or higher pressure differentials.

Industrial Applications and Market Segments

Stamped iron solenoid valve housings serve critical functions across diverse industrial sectors where reliable fluid control is essential. Their combination of electromagnetic efficiency, mechanical strength, and cost-effectiveness makes them the preferred choice for high-volume applications.

Automotive and Transportation Systems

The automotive industry consumes approximately 40% of global solenoid valve production, utilizing stamped iron housings in transmission control systems, fuel injection assemblies, and emissions management. Modern automatic transmissions incorporate 8-12 solenoid valves operating at pressures up to 30 bar with response times under 50 milliseconds. The stamping process enables integration of mounting features and connector interfaces directly into the housing, reducing assembly complexity and component count.

HVAC and Refrigeration Equipment

Commercial refrigeration systems and building climate control utilize stamped iron solenoid valves for refrigerant flow management. These applications benefit from the thermal conductivity of iron housings, which helps dissipate heat from continuous-duty coils operating at ambient temperatures ranging from -40°C to +65°C. Industry specifications require 100,000+ cycle life for HVAC solenoid valves, a target readily achieved with properly designed stamped housings.

Industrial Automation and Process Control

Manufacturing facilities employ pneumatic and hydraulic systems incorporating thousands of solenoid valves for actuator control, material handling, and process sequencing. Stamped iron housings in these applications typically feature G1/8 to G1/2 port sizes with direct-acting or pilot-operated valve mechanisms. The consistent magnetic properties of stamped iron ensure reliable operation across production runs spanning millions of cycles.

Cost Analysis and Economic Advantages

The economic benefits of stamped iron solenoid valve housings extend beyond raw material costs to encompass manufacturing efficiency, inventory management, and total cost of ownership considerations.

Manufacturing Cost Breakdown

Comparative analysis of housing production methods reveals significant cost differences:

- Stamped iron: $0.45-$1.20 per unit at volumes above 50,000 pieces annually

- Cast iron: $1.50-$2.80 per unit with additional machining operations required

- Machined stainless steel: $3.50-$6.50 per unit with extended lead times

- Powder metallurgy: $1.80-$3.20 per unit with limited geometry options

The tooling investment for progressive dies ranges from $25,000 to $75,000 depending on complexity, but this cost is amortized over production runs typically exceeding 500,000 units. At moderate volumes (100,000+ units annually), stamped iron achieves break-even within 6-12 months compared to alternative manufacturing methods.

Lifecycle Cost Considerations

Field reliability data indicates that properly designed stamped iron housings achieve mean time between failures (MTBF) exceeding 50,000 operating hours in typical industrial environments. The primary failure modes relate to seal degradation and coil burnout rather than housing structural issues, confirming that stamped iron provides adequate durability for most applications without the premium cost of exotic materials.

Future Developments and Industry Trends

Ongoing research in materials science and manufacturing technology continues to enhance the capabilities of stamped iron solenoid valve housings. Advanced high-strength low-alloy (AHSLA) steels offer 20-30% strength improvement while maintaining excellent magnetic properties, enabling further weight reduction and miniaturization.

Additive manufacturing of stamping dies using metal 3D printing reduces tooling lead times from 12-16 weeks to 4-6 weeks, facilitating rapid prototyping and design iteration. Industry forecasts project that stamped metal components will maintain 65-70% market share in solenoid valve housings through 2030, driven by their unmatched combination of performance, cost, and manufacturing scalability.

Integration of IoT sensors and smart valve technology creates new requirements for housing designs that accommodate electronic components while preserving electromagnetic performance. Hybrid manufacturing approaches combining stamped housings with overmolded plastics or selective laser welding enable these advanced features without compromising the fundamental advantages of stamped iron construction.