Copper-based plated stamping parts are widely used across industries due to their excellent electrical conductivity, corrosion resistance, and adaptability to various mechanical applications. However, when these parts are exposed to high-stress environments, questions often arise regarding their durability and long-term performance. Understanding the factors that influence the strength and lifespan of these components is critical for engineers, designers, and manufacturers who rely on them in demanding applications.

1. Understanding Copper-Based Plated Stamping Parts

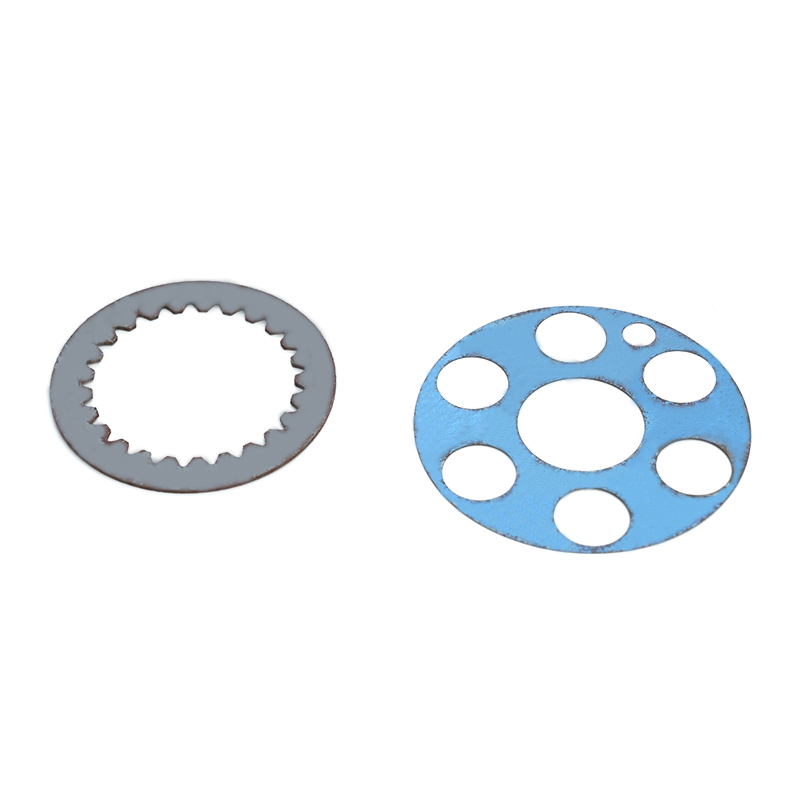

Copper-based plated stamping parts are typically manufactured by stamping thin copper or copper-alloy sheets into specific shapes and then applying a plating layer, often nickel, tin, or other protective metals. The plating serves multiple purposes: it enhances corrosion resistance, improves surface conductivity, and increases wear resistance.

The combination of copper’s intrinsic properties with the protective plating makes these parts suitable for use in electronics, automotive components, industrial machinery, and aerospace applications, where they are often subjected to repetitive stress, high temperatures, and mechanical loads.

2. Key Factors Affecting Durability

The durability of copper-based plated stamping parts under high stress is not determined solely by the material itself but by a combination of design, manufacturing, and environmental factors.

a. Material Quality

The base copper or copper alloy’s purity, grain structure, and thickness significantly impact durability. High-purity copper offers excellent conductivity but may be softer and more prone to deformation under stress. Alloys such as brass or bronze provide a balance between conductivity and mechanical strength, making them more resilient in high-stress scenarios.

b. Plating Type and Thickness

The type and thickness of the plating layer also play a crucial role. Nickel plating, for example, provides high hardness and wear resistance, while tin or silver plating can enhance conductivity but may be softer. Uneven plating or insufficient thickness can create weak points, reducing the part’s ability to withstand mechanical stress.

c. Manufacturing Process

The stamping process itself affects durability. Factors such as stamping pressure, die design, and precision influence the internal stress distribution within the part. Poorly executed stamping can result in microcracks, work hardening, or residual stress, which may compromise durability under load.

d. Environmental Conditions

High-stress applications are often accompanied by harsh environmental conditions, including temperature fluctuations, humidity, and exposure to chemicals. Copper-based plated parts can corrode if the plating is damaged or if incompatible materials are present, leading to reduced mechanical performance and failure under stress.

3. Mechanical Stress and Its Impact

High-stress conditions for stamping parts can include tensile stress, bending, shear, vibration, and impact. Each type of stress affects copper-based plated parts differently:

- Tensile Stress: Pure copper may stretch or deform under sustained tensile loads. Plated layers with higher hardness can help resist stretching, but excessive load may cause delamination between the plating and base material.

- Bending Stress: Thin copper stamping parts are susceptible to bending or flex fatigue. Proper alloy selection and work hardening techniques during stamping can enhance resistance.

- Shear and Impact Stress: In applications where parts experience sudden loads, copper alloys with high toughness and durable plating are preferred to avoid cracking or chipping.

4. Testing Durability Under High Stress

Evaluating the durability of copper-based plated stamping parts requires a combination of laboratory tests and real-world simulations. Common testing methods include:

- Tensile Testing: Measures the maximum stress a part can withstand before breaking.

- Bend and Flex Tests: Assess resistance to repeated bending and fatigue.

- Corrosion Testing: Simulates exposure to moisture, salt, or chemicals to evaluate plating integrity.

- Thermal Cycling: Determines how the part responds to repeated temperature fluctuations.

These tests help engineers identify potential weak points and optimize material selection, plating type, and stamping techniques to improve performance.

5. Design Considerations for High-Stress Applications

Durability can often be enhanced through thoughtful design. Key considerations include:

- Uniform Wall Thickness: Avoiding thin sections or sharp corners reduces stress concentration.

- Smooth Transitions: Rounded edges and chamfers minimize stress risers where cracks can initiate.

- Optimized Plating: Ensuring sufficient plating thickness and adhesion improves resistance to wear and corrosion.

- Alloy Selection: Choosing copper alloys with higher mechanical strength or integrating reinforcement features can enhance performance without sacrificing conductivity.

6. Maintenance and Longevity

Even the most well-designed copper-based plated stamping parts require maintenance to achieve long-term durability under stress. Key maintenance strategies include:

- Regular Inspections: Look for signs of wear, corrosion, or plating delamination.

- Environmental Protection: Reduce exposure to corrosive chemicals or moisture when possible.

- Proper Handling: Avoid excessive mechanical force during installation or operation to prevent microcracks.

7. Practical Applications and Performance Expectations

Copper-based plated stamping parts are used in a variety of high-stress applications, including:

- Electrical connectors in high-current circuits.

- Automotive sensors and contacts exposed to vibration.

- Aerospace components requiring reliable mechanical and electrical performance.

- Industrial machinery that experiences repetitive mechanical loading.

When properly designed, manufactured, and maintained, these parts can withstand significant stress while maintaining functionality. However, the exact lifespan depends on the combination of material selection, plating quality, mechanical load, and environmental exposure.

8. Conclusion

Copper-based plated stamping parts offer a versatile combination of electrical conductivity, corrosion resistance, and mechanical performance. Under high-stress conditions, their durability depends on careful material selection, plating quality, precise stamping techniques, and thoughtful design. By understanding the factors that influence performance and implementing proper testing, design, and maintenance strategies, engineers and manufacturers can ensure these components perform reliably in demanding applications.

While no part is indestructible, copper-based plated stamping parts, when engineered and maintained properly, provide a durable and cost-effective solution for many high-stress environments.