Stainless steel is a cornerstone of modern manufacturing, prized for its corrosion resistance, strength, and sleek appearance. When it comes to forming this versatile material into precise shapes, stamping is a highly efficient and common process. A question that frequently arises for engineers, designers, and procurement specialists is whether stainless steel stamping parts require heat treatment. The answer, like many in engineering, is not a simple yes or no. It depends entirely on the intended function of the part, the specific grade of stainless steel, and the manufacturing challenges encountered during stamping.

Understanding the role of heat treatment is crucial for ensuring a stamped component performs as expected in its final application. Let’s explore the reasons why heat treatment might be necessary, the different types used, and the scenarios where it can be safely omitted.

Understanding the “Why”: The Goals of Heat Treatment

Heat treatment is a controlled process of heating and cooling metals to alter their physical and mechanical properties without changing the product’s shape. For stamped stainless steel parts, the primary objectives are:

- Stress Relief (Annealing): To remove internal stresses induced by the stamping process.

- Softening (Annealing): To restore ductility and improve formability for subsequent manufacturing steps.

- Hardening: To increase the part’s surface hardness, wear resistance, and strength.

- Enhancing Corrosion Resistance: To restore the protective passive layer of the material, which can be compromised during deformation.

Whether you need to achieve one of these goals dictates if and what type of heat treatment is required.

The Impact of the Stamping Process: Work Hardening

To understand the need for heat treatment, one must first understand a key characteristic of stainless steel: work hardening. As stainless steel is deformed, punched, or bent during stamping, its crystal structure becomes distorted. This distortion makes the material harder, stronger, but also significantly more brittle and less ductile.

This is a double-edged sword. For some applications, a bit of increased strength from work hardening is beneficial. However, for complex stamping operations involving deep draws or severe bends, excessive work hardening can lead to cracking, tearing, or premature tooling failure. It is this very phenomenon that often drives the need for an intermediate or final heat treatment.

When Heat Treatment is Necessary

Heat treatment becomes a critical step in the manufacturing process in the following scenarios:

1. Between Stamping Stages (Process Annealing)

In multi-stage stamping operations, particularly deep drawing, a part may need to be annealed between steps. As the metal is drawn into a deep cavity, it work hardens to the point where further deformation would cause it to crack. A process anneal—heating the part to a specific temperature and then cooling it—softens the material by recrystallizing its grain structure, restoring its ductility and allowing for the next drawing operation to be performed successfully.

2. To Restore Corrosion Resistance

The deformation from stamping can disrupt the uniform chromium oxide layer on the surface of stainless steel, which is responsible for its “stainless” property. While the passive layer can often re-form in the presence of oxygen, parts used in highly corrosive environments (e.g., marine, chemical processing) may require a post-stamping anneal followed by pickling and passivation. This process ensures the optimal chromium oxide layer is restored, guaranteeing maximum corrosion resistance.

3. To Achieve Specific Mechanical Properties (Hardening)

This applies almost exclusively to martensitic stainless steels (e.g., grades 410, 420, 440C). Unlike the more common austenitic grades (304, 316), martensitic steels can be hardened through heat treatment. The process typically involves:

- Austenitizing: Heating the stamped part to a high temperature.

- Quenching: Rapidly cooling it in oil or air to form a hard, brittle martensitic structure.

- Tempering: Re-heating to a lower temperature to reduce brittleness and achieve the desired balance of hardness and toughness.

This is essential for parts like cutlery blades, surgical instruments, and bearing components, where high hardness and wear resistance are mandatory.

4. To Relieve Residual Stresses for Dimensional Stability

Even if a part doesn’t crack during stamping, the residual stresses locked into the material can cause it to warp or change shape slightly over time, or during subsequent machining operations. A stress relief anneal performed at a lower temperature than a full anneal can stabilize the part, ensuring it maintains its precise dimensions. This is critical for components used in assemblies with tight tolerances.

When Heat Treatment Can Be Omitted

Heat treatment adds cost, time, and energy consumption to the manufacturing process. Therefore, it is avoided whenever possible. It is often unnecessary for:

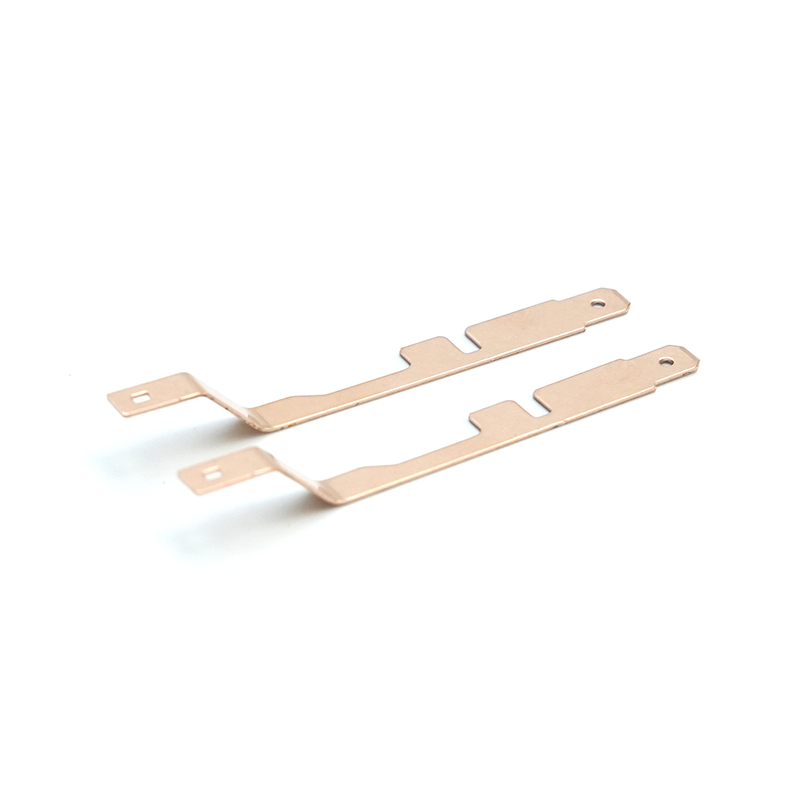

- Simple, Low-Strain Parts: Components made with simple bends or shallow draws that do not significantly work-harden the material.

- Non-Critical Cosmetic Parts: Where mechanical properties and maximum corrosion resistance are not primary concerns (e.g., some decorative trims or covers).

- Parts Where Work Hardening is Beneficial: In some cases, the increased strength from the stamping process itself is a design feature and is sufficient for the part’s function.

Common Types of Heat Treatment for Stamped Parts

- Full Annealing: Heats the metal to a high temperature and slowly cools it to produce a soft, ductile microstructure. Used for severe work hardening recovery.

- Process Annealing (Intermediate Annealing): Performed at a lower temperature than full annealing, specifically to soften metal between forming stages.

- Stress Relieving: Heats the part to a temperature below its lower critical temperature to reduce internal stresses without significantly altering the microstructure.

- Solution Annealing & Quenching: Primarily for austenitic stainless steels, it involves heating to a high temperature to dissolve carbides and then rapidly quenching to prevent their re-formation, restoring optimal corrosion resistance and ductility.

- Heat Treating & Tempering: The specific hardening process for martensitic stainless steels, as described above.

Conclusion: A Strategic Decision, Not a Default

So, do stainless steel stamping parts require heat treatment? The requirement is not inherent to the stamping process itself but is a strategic decision based on the interplay of three factors:

- The Material Grade: Is it an austenitic grade that work-hardens, or a martensitic grade that can be quenched-and-tempered?

- The Part’s Function: Does it require maximum strength, ductility, hardness, or corrosion resistance?

- The Manufacturing Process: How severe is the deformation? Does it involve multiple deep draws?

By carefully evaluating the application and the manufacturing journey of the part, engineers can make an informed decision on whether to incorporate heat treatment, ensuring the final stamped component meets its performance and longevity goals without incurring unnecessary cost.

| Scenario | Likely Need for Heat Treatment | Type of Heat Treatment |

| Deep Drawing in Multiple Stages | High | Process Annealing (between stages) |

| Part for a Highly Corrosive Environment | High | Solution Annealing & Passivation |

| Part Requiring High Hardness (e.g., blade) | High | Hardening & Tempering (for martensitic grades) |

| Part with Critical Dimensional Tolerances | Likely | Stress Relieving |

| Simple Bracket or Non-Critical Cover | Low/None | Omitted |